Popis

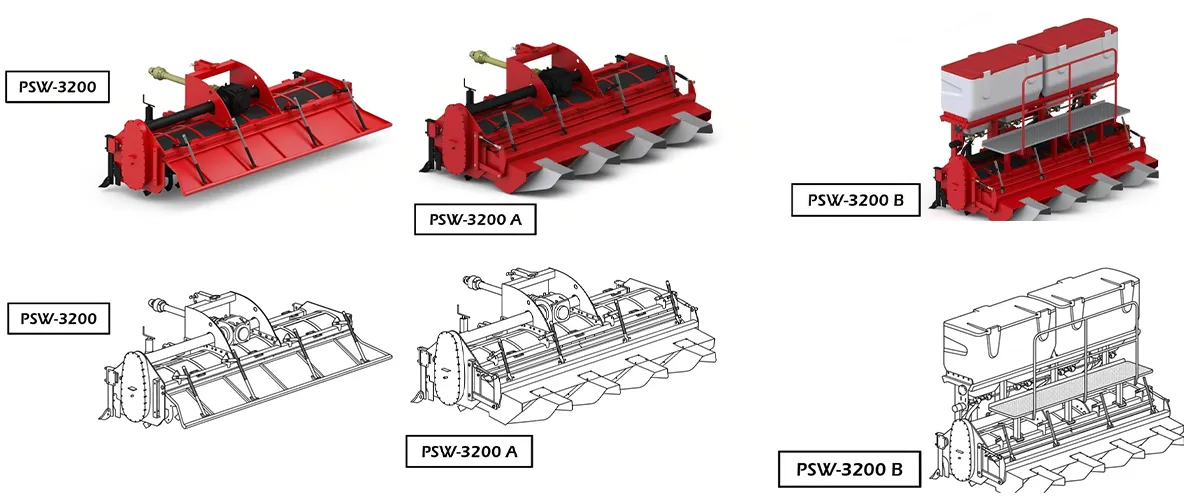

1. Technical Specifications: PSW-3200

| Feature | PSW-3200 A (Rotavator) | PSW-3200 B (Rotavator) | EW-4000 (Rock Rake) |

|---|---|---|---|

| Working Width | 3.20 m | 3.20 m | 3.6 m |

| Bunker Capacity | N/A | 2000 Kg (Fertilizer) | N/A |

| Weight | 1665 Kg | 1800 Kg | 1900 Kg |

| Min. Engine Power | 140 cv | 140 cv | 100 cv |

| Working Speed | 3-5 km/h | 3-5 km/h | 3-5 km/h |

| Category Linkage | Cat 2 | Cat 2 | Cat 2 |

2. FIVE Key Facts

- Dual-Function Capability: The PSW-3200 B model combines deep-soil tillage with high-capacity fertilization, allowing one-pass soil preparation that saves up to 40% in fuel costs.

- Extreme Durability: Constructed with high-strength alloys and a Category 2 bottom linkage, these machines are rated for tractors up to 140 cv, handling the toughest Korean clay and stony loams.

- Pre-Tillage Stone Management: Using a rock rake for tractor prior to the PSW-3200 eliminates mechanical shock from boulders, extending rotavator gear life by over 65%.

- Precision Working Speed: Both the rotavator and the rock rake are calibrated for an optimal 3-5 km/h operation, ensuring thorough pulverization without compromising soil structure.

- Reclamation Compliance: Our equipment meets the South Korean “Farmland Act” and “Mountainous Districts Management Act” regarding responsible stone removal and soil conservation.

3. The core advantage of PSW-3200 Rotavator

The PSW-3200 series is designed for large-scale operations and demanding agricultural environments. In South Korea, as the focus of agriculture shifts towards efficient “smart farming” (스마트팜) and mountain cultivation, the PSW-3200 stands out as an indispensable piece of equipment.

The machine’s core advantage lies in its 3.20-meter working width, achieving an ideal balance between cultivated area and tractor maneuverability. The series comes in two main configurations: the PSW-3200 A, a high-performance standard rotary tiller; and the PSW-3200 B, equipped with a massive 2000 kg fertilizer hopper.

This “B” configuration is particularly revolutionary for Korean ginseng and potato growers, as it allows for the precise application of nutrients deep into the cultivated soil in a single pass. By reducing the number of tractor passes, soil compaction is minimized—crucial for maintaining the long-term health of South Korea’s limited arable land. The heavy-duty drive system and precisely designed blades ensure a tillage depth exceeding 25 cm, effectively breaking up the plow pan and ensuring good soil aeration to promote crop root growth.

4. Rock Rake Integration: Protecting Your Investment

Operating high-end rotary tillers in rocky areas like Jeju Island or the highlands of Gangwon Province poses significant risks to the equipment. A single collision with a buried boulder can lead to broken tiller blades or damage to the power take-off (PTO) drive system.

Our company addresses this problem with specialized rock rakes for tractor attachments, such as the EW-4000 series. This equipment acts as an industrial-grade landscape rake, with a working width of 3.6 meters, raking rocks, roots, and debris into rows before cultivation.

Whether you use a powered rock rake or a more traditional stone rake, the goal is the same: to clear a safe path for the PSW-3200 rotary tiller. The EW-4000 utilizes high-strength spring steel tines to sift the topsoil and rake out rocks ranging from pebbles to large boulders. For B2B contractors in Korea, having a rock rake in their fleet is not a luxury but a necessity for soil improvement projects, as the soil in these regions is often rich in glacial or volcanic rocks. This proactive approach ensures smooth and even cultivation with the PSW-3200 and prevents catastrophic mechanical failures.

5. Legal Standards & Land Management Compliance

Adherence to local and international laws is paramount when deploying heavy-duty land management equipment like a rock rake attachment. In South Korea, the Farmland Act (농지법) strictly regulates any activity that might degrade soil quality or alter the designated use of the land. When utilizing rock rake for skid steer or tractor units for land clearing, operators must ensure that topsoil loss is minimized. Furthermore, the Environmental Impact Assessment Act in Korea may apply to large-scale stone removal and soil redistribution projects to prevent erosion and runoff into local water systems. Watanabe equipment is designed to comply with these standards by allowing for high-precision depth control, ensuring only the debris is removed while the vital topsoil remains. Globally, our machinery adheres to the EU Machinery Directive 2006/42/EC and ISO 4254-1 for agricultural safety. In the United States, the USDA’s Natural Resources Conservation Service (NRCS) provides guidelines for rock removal that align with our machine’s technical capabilities, promoting “soil health” by preventing over-tilling. Compliance with the Occupational Safety and Health Act (OSHA) is also maintained through our integrated safety shields and emergency shut-off compatibility with modern tractor PTO systems.

6. Brand & Component Compatibility

| Tractor Brand | Model Series (Korea Spec) | Compatibility Rating |

|---|---|---|

| LS Mtron | MT7 / XP Series (120hp+) | Perfect Fit (Cat 2) |

| TYM (Tong Yang) | T110 / T130 Series | Direct Mount |

| Kubota | M7 Series (High HP) | Full Integration |

| John Deere | 6M / 6R Series (140hp+) | Highly Compatible |

7. Industry Trends: Soil Management in 2025

The agricultural sector in 2025 is defined by “One-Pass” efficiency and data-driven tillage. In South Korea, the rising cost of labor and fuel has pushed farmers to adopt multi-functional implements like the PSW-3200 B. There is a clear trend toward equipment that integrates soil chemistry (fertilization) with soil physics (tillage).

Furthermore, as the world faces climate instability, the need for robust pre-tillage stone clearing using a rock rake for tractor or power rock rake has surged. Farmers are no longer willing to risk downtime due to equipment breakage in rocky soil. Instead, they are investing in heavy-duty landscape rake systems to prepare the ground for decades of productive use. Additionally, the adoption of small rock rake attachments for atv or skid steer units is growing among horticulturalists and hobby farmers who require the same precision as industrial farms but on a compact scale.

8. World Success Case

Client 1 Profile:

Company: Jeju Island Agricultural Solutions, South Korea

Customer Reviews:

“We’ve been using the EW-4000 rock rake before preparing soil with the PSW-3200, and the combination is perfect for our rocky land. The rock rake efficiently clears debris, so the rotavator can do its job without any interruptions. The quality of the equipment is exceptional, and it’s made a huge difference in soil preparation here in Jeju, where the terrain is tough and rocky.”

Client 2 Profile:

Company: Tractor Dealers, South Korea

Customer Reviews:

“As a distributor of tractors, we highly recommend the PSW-3200 series and the EW-4000 rock rake to our customers. The PSW-3200 B model with the fertilizer hopper is especially great for large-scale operations, and the rock rake makes pre-tillage stone management much easier. The equipment is durable, efficient, and perfect for South Korea’s soil conditions.”

Client 3 Profile:

Company: Potato Farmers Co-op, United States

Customer Reviews:

“We’ve been using the PSW-3200 for years to prepare our soil for potatoes, and adding the rock rake to the mix has been a game-changer. The rocky soil here in the Midwest would often cause damage to our rotavator, but with the rock rake clearing debris first, our equipment lasts longer, and we’re able to work more efficiently. We highly recommend it!”

Client 4 Profile:

Company: Agri-Construction Ltd, United Kingdom

Customer Reviews:

“We use the EW-4000 rock rake and PSW-3200 together for land reclamation and agricultural site preparation in the UK. The rock rake is perfect for clearing debris, and the PSW-3200 makes soil tilling efficient, even in heavy clay soils. The equipment is robust and reliable, and it has allowed us to reduce labor costs and speed up our operations significantly.”

9. EVER-POWER Factory Capabilities & OEM Customization

We understand that soil conditions vary not only from country to country but also within different regions of the same country.

Our manufacturing facilities are equipped with advanced CNC machining equipment and robotic welding production lines, enabling us to provide exceptional customized services.

Unlike traditional fixed assembly lines, we can adjust the chassis reinforcement, tooth spacing, and hydraulic line layout of our rock rakes to suit specific regional needs, such as adapting to the heavy clay soils common in Southeast Asia or the dry, abrasive soils of the Middle East.

We offer OEM services to our distributors and can customize the connection system to suit specific tractors.

Whether you need a rock rake configuration for road construction or specialized equipment for agricultural production, our engineering team is ready to assist you.

10. About us

– Rock & Soil Equipment: Rock rakes, rock pickers, rotavators, rotary cultivators

– Potato-Specific Machinery: Potato planters, potato furrowers, potato diggers (2-row, trailed, 2-row trailed, 4-row trailed), potato harvesters (2-row, big-bag compatible), potato processing auxiliary equipment

– Livestock Machinery: Specialized equipment for livestock farming operations

– Agricultural Inputs: High-performance fertilizers

11. Replaceable parts

11.1. PTO Drive Shaft and PTO Gearbox

1. PTO Shaft

2. Agricultural Gearboxes / PTO Gearboxes

11.2. Agricultural Gearboxes (including various applications)

1. Rotary tiller gearboxes

2. Fertilizer spreader gearboxes

3. Rake & mower PTO gearboxes

11.3. Hydraulic Cylinders

1. Standard hydraulic cylinders

2. Custom hydraulic cylinders

11.4. Drive Chains / Sprockets / Couplings / Gear Components

1. Roller Chains

2. Chains & Sprockets

3. Couplings

12. Frequently Asked Questions

Q1. What is the average rotavator price for a heavy-duty PSW-3200 model delivered to a farm in South Korea?

A1. The cost of a Watanabe PSW-3200 rotavator depends significantly on whether you choose the standard ‘A’ model or the fertilizer-integrated ‘B’ model. Generally, B2B quotes include shipping and customs duties for the Korean market; for the most accurate pricing tailored to your region’s specific logistics, we recommend clicking our “Get a Quote” button to receive a detailed breakdown based on current import tariffs and currency exchange rates.

Q2. How do I choose between a 3-point hitch rock rake attachment and a towed rock rake machine for rocky soils in Gangwon highlands?

A2. When working in the steep and rocky terrains typical of Gangwon-do, the choice depends on your tractor’s lift capacity and the size of the debris. A 3-point hitch rock rake attachment like the EW-4000 offers superior maneuverability in tighter fields, while a towed rock rake machine is better suited for larger, flatter reclamation projects where stability and depth control are the primary concerns for removing heavy boulders.

Q3. Can a standard 100hp tractor handle the working width of the PSW-3200 B rotavator with a full fertilizer bunker?

A3. While a 100hp tractor may be able to turn the rotavator blades, Watanabe recommends a minimum of 140 cv (horsepower) for the PSW-3200 series, especially the ‘B’ model. When the 2000kg bunker is full, the additional weight requires a tractor with significant hydraulic lift capacity and engine torque to maintain the optimal 3-5 km/h working speed required for high-quality soil pulverization in dense Korean soils.

Q4. Where can I find a reliable supplier in Korea for specialized gravel rake or landscape rake attachments for skid steer loaders?

A4. Watanabe works with authorized distributors across South Korea, from Gyeonggi-do to Jeju. We specialize in industrial-grade gravel rake and landscape rake solutions that are fully compatible with local skid steer brands. If you are looking for a supplier that understands the specific stony composition of Korean soil, our technical support team can connect you with a local expert who stocks the EW-4000 series.

Q5. Which specific materials are used in Watanabe rock rake tines to prevent bending when hitting granite or volcanic stones?

A5. We utilize high-grade boron steel and specialized heat-treated spring alloys for all our rock rake for tractor components. This ensures that the tines have the “memory” to return to their original shape after impact. In stony Korean fields, this durability is vital, as standard steel tines would quickly deform under the extreme pressure of clearing granite or volcanic basalt commonly found in the region.

Q6. Why is it necessary to use a power rock rake before a rotavator tiller on newly reclaimed farmland in South Korea?

A6. Using a power rock rake or rock rake machine is the most effective way to ensure “soil health” compliance under the Farmland Act. By removing stones first, you allow the rotavator tiller to work at a consistent depth without the risk of mechanical shock. This synergy creates a perfect seedbed for high-value crops like Korean ginseng, where root growth is easily stunted by buried rocks and compacted soil layers.

Q7. What is a rotavator used for?

A7. A rotavator is an agricultural machine used for tilling the soil. It is primarily used to prepare the ground for planting by breaking up compacted soil, mixing in fertilizers, and sometimes incorporating organic material into the soil. It helps in creating a fine seedbed for crops, improving soil aeration, and controlling weeds. Rotavators are commonly used for plowing, seedbed preparation, and soil mixing in farming and gardening.

Q8. What is the difference between a tiller and a rotavator?

A8. While both tillers and rotavators are used to prepare the soil, their main differences lie in their design and mechanism:

Tiller: Typically, a tiller is a smaller, simpler machine designed for shallow tilling of the soil. Tillers often have a set of rotating blades or tines that dig into the soil to turn it over. They are more suitable for small-scale gardening or light-duty tasks.

Rotavator: A rotavator is a more powerful and industrial-grade machine designed for deeper and more thorough tilling. It has a set of heavier-duty rotating blades or discs that break up and mix soil more effectively than a standard tiller. Rotavators are used for larger agricultural operations, especially when the soil needs to be deeply broken up and prepared for planting.

Q9. What is a rotavator in England?

A9. In England, a rotavator refers to a mechanized soil tilling machine, similar to its use elsewhere. The term rotavator is often associated with garden tillers or motorized cultivators in the UK. It typically refers to a machine used in horticulture and agriculture for breaking up soil, mixing in compost or fertilizer, and preparing the ground for planting. The term is widely used in the UK to describe these machines, especially in home gardening and small-scale farming.

Q10. What is another name for a rotavator?

A10. Another name for a rotavator is a rotary tiller or garden tiller. Depending on the region and specific type of equipment, it can also be referred to as a cultivator or soil cultivator. These names generally refer to machines with rotating blades or discs used to break up soil and prepare it for planting.

Editor: PXY

*Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.