Описание

1. Technical Engineering Specifications: CT-2100 Series

| Parameter / Feature | Technical Data (CT-2100) | Engineering Implication |

|---|---|---|

| Total Dimensions (L x W x H) | 6000 mm x 3050 mm x 2340 mm | High capacity frame stability for uneven terrain loads. |

| Gross Weight | 3400 Kg | Heavy-duty construction ensures durability against abrasive granite. |

| Working Width | 1.95 meters | Optimized for standard Korean tractor wheelbases and farm lanes. |

| Bunker Capacity | 2.5 m³ | Reduces dumping frequency, increasing operational uptime. |

| Tractor Power Requirement | Min. 110 cv (HP) | Requires robust PTO and hydraulic output for continuous operation. |

| Hydraulic Oil Flow | 60 L/min | Ensures consistent torque in the pick-up reel mechanism. |

| Working Speed | 3 – 5 km/h | Precision speed for maximum stone separation and minimal soil loss. |

| Linkage Category | Category 2 | Standardized compatibility for mid-to-large range agricultural tractors. |

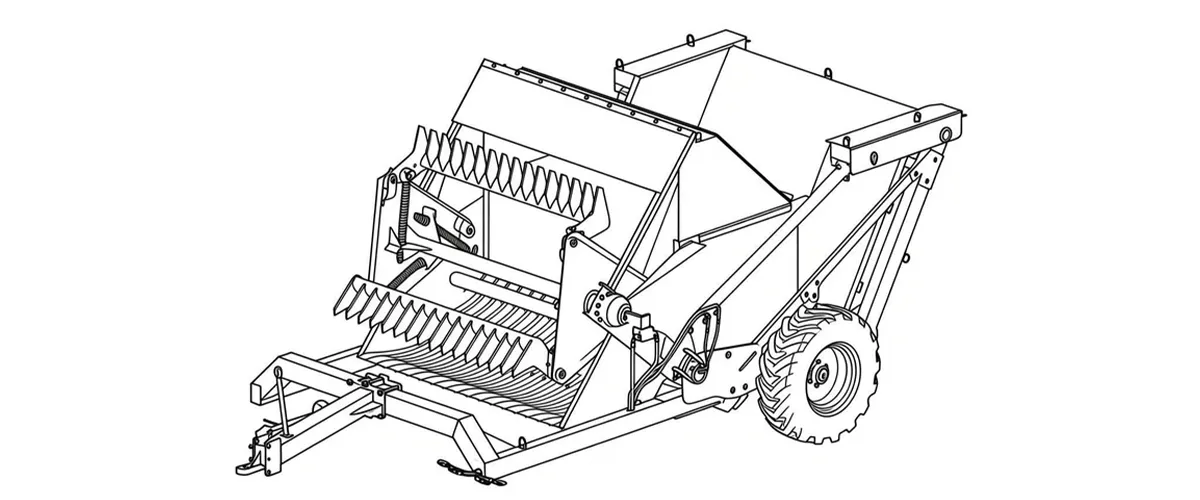

2. EP-CT-2100 Rock Picker Overview

South Korea’s agricultural landscape is characterized by mountainous terrain and granite-rich soils, presenting unique challenges for modern farming and land cultivation. The Watanabe CT-2100 stone collector is more than just a machine; it’s a strategic engineering solution designed to address these demanding conditions.

Unlike conventional equipment that often fails under the pressure of heavy basalt or granite rocks common in regions like Gangwon-do or Gyeongsangbuk-do, the CT-2100 features a robust hydraulic drive system specifically calibrated for high performance and durability.

The machine is designed to systematically remove stones from fields that can damage harvesting equipment, hinder the root growth of high-value crops like ginseng and potatoes, and reduce the overall value of the land. Integrating the CT-2100 into your workflow means not only clearing debris but fundamentally transforming soil structure to meet the standards of precision agriculture. The machine’s design emphasizes longevity and reduced downtime, ensuring that critical spring planting operations are not interrupted by the mechanical failures common with inferior stone collectors.

Furthermore, the CT-2100’s application perfectly aligns with the growing trend of mechanization efficiency in East Asia. With increasing labor shortages in rural South Korea, relying on manual stone picking is no longer economically viable. The CT-2100’s 1.95-meter working width allows for rapid coverage of large areas in a single pass. This efficiency is crucial for preparing land for specialized crops that require deep, stone-free soil for optimal tuber expansion or root penetration. When used in conjunction with power stone collectors or landscape rakes for initial piling, the CT-2100 acts as the final collection unit, gathering the piled debris with high precision. The Category 2 three-point hitch design ensures stability on uneven terrain.

3. Working Principle, Metallurgy & Application Scenarios

3.1. Advanced Hydraulic Picking Mechanism

The Watanabe CT-2100 operates on a sophisticated hydraulic-driven rotary principle. Unlike a static rock rake for skid steer which drags debris, the CT-2100 actively lifts. As the tractor moves forward, the heavy-duty tines dig slightly into the soil surface. The hydraulic reel, powered by the tractor’s 60 L/min oil flow, sweeps stones onto a screening grate. The soil falls back through the grate while the stones are conveyed into the expansive 2.5 m³ rear bunker. This active separation ensures that topsoil retention is maximized—a critical factor for sustainable farming in regions with thin topsoil layers. The high dumping height allows for easy offloading into trucks or piles at the field edge.

3.2. Material Composition & Durability

Durability is paramount when dealing with abrasive lithology. The mainframe of the CT-2100 is constructed from high-tensile structural steel (comparable to Q345B or S355), providing the necessary rigidity to withstand torsion on uneven ground. The pick-up tines and the screening grate are manufactured using heat-treated, wear-resistant alloy steel (typically manganese or boron steel derivatives), offering a hardness rating often exceeding 45-50 HRC. This ensures that even after hundreds of hours of contact with abrasive silica-rich rocks, the wear components maintain their structural integrity. This is a significant upgrade over a standard small rock rake or gravel rake often found in residential gardening, which utilizes milder steels unsuited for agricultural-scale operations.

3.3.Synergy with Rock Rake Attachments

While the CT-2100 is a powerhouse collector, its efficiency is doubled when paired with a rock rake attachment. In a typical workflow, a farmer would first use a rock rake for tractor or a rotary landscape rake to windrow scattered surface stones into neat lines. Once windrowed, the CT-2100 follows the line, picking up the concentrated volume of stone. This two-step process reduces the number of passes required by the heavy picker, saving fuel and reducing soil compaction. For smaller operations or tight corners where the CT-2100 cannot reach, a rock rake for atv or a rock rake hand tool might be used for spot cleaning, ensuring comprehensive field management.

4. Global Trends & Regulatory Compliance

Regulatory Landscape: In South Korea, the Farmland Act emphasizes the preservation of soil productivity and the prevention of land degradation. Excessive stoniness is classified as a hindrance to mechanization, often requiring remediation to qualify for certain agricultural subsidies or to maintain land value classifications. Furthermore, in construction projects involving land reclamation, strict regulations govern the disposal of excavated rock and soil separation. The CT-2100 facilitates compliance by efficiently separating rock (which can be crushed and repurposed as aggregate) from soil, adhering to resource recycling mandates. Similarly, in markets like Europe and North America, soil conservation laws (such as cross-compliance rules in the CAP) mandate minimizing soil erosion; the CT-2100’s ability to pick stones without stripping vegetation cover or topsoil aligns perfectly with these environmental standards.

Market Trends: The global trend in stone management is shifting towards “Precision Land Reclamation.” Operators are moving away from simple burial or manual removal towards mechanical harvesting of rock for crushing. The demand for rock rake machines and pickers is rising in correlation with the adoption of precision seeders, which have zero tolerance for stone impact. There is also a growing trend in the “rental economy” for such specialized equipment. In South Korea, agricultural machinery rental banks are increasingly stocking heavy-duty pickers like the CT-2100 to serve multiple small-hold farmers who cannot justify the purchase of a rock rake attachment or picker individually. This shared-economy model demands equipment with extreme durability and low maintenance requirements—core attributes of the Watanabe engineering philosophy.

5. Compatibility & Equipment Synergy

| Equipment Type | Role in Stone Management | Synergy with CT-2100 |

|---|---|---|

| Rock Rake for Tractor | Windrowing scattered stones into lines. | High: Prepares the field for the CT-2100 to pick up efficiently in one pass. |

| Rock Rake for Skid Steer | Clearing tight spaces, corners, or construction sites. | Medium: Cleans areas the large CT-2100 cannot reach. |

| Landscape Rake / Leaf Rake | Light debris removal (twigs, leaves, small gravel). | Low: Used for finishing touches after the heavy lifting is done. |

| Stone Crusher (PTO Driven) | Crushing rocks in-situ rather than removal. | Alternative: The CT-2100 removes rock; crushers destroy it. Choice depends on soil goals. |

*Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.

6. Application Scenarios:

1. South Korean mountainous agriculture – Efficient rock removal to protect crops

2. Australian vast farmlands – Land preparation and crop planting

3. American farms – Efficient rock removal to increase crop yields

4. French vineyards – Rock removal without damaging soil structure

5. Middle Eastern desert agriculture – Overcoming rock removal challenges in arid regions

6. European land reclamation – Rock removal and environmental protection

7. Southeast Asian small farms – Efficient rock removal to improve productivity on small farms

7. World Success Case:

Customer 1 Profile:

Company: Gangwon-do Construction and Land Development Company, South Korea

Customer Review:

“As a contractor working in the mountainous regions of Gangwon-do, the CT-2100 has significantly improved our land reclamation projects. The terrain here is rugged, and traditional methods often fail against the hard basalt rock. This stone picker is robust and reliable. We can use it in various conditions with minimal downtime, which helps us complete projects on schedule. The high dumping height is also a great advantage, allowing for easy unloading of stones onto trucks.”

Customer 2 Profile:

Company: North American Organic Farm, USA

Customer Review:

“As an organic farm in the United States, we are always looking for equipment that is both efficient and soil-friendly. The CT-2100 fits our requirements perfectly. It effectively removes stones while ensuring we don’t lose valuable topsoil. We have used it in our potato fields, and it has been remarkably effective in removing large stones without affecting the crop’s root structure. It’s a robust and durable machine, and so far, we haven’t encountered any durability issues.”

Customer 3 Profile:

Company: Middle East Farm, Saudi Arabia

Customer Review:

“We operate a farm in the desert region of Saudi Arabia, where rocky terrain and limited labor are significant challenges. The CT-2100 has dramatically improved our efficiency. Previously, we used smaller machines that couldn’t handle the rocky terrain, but now we can clear large areas quickly. Its powerful hydraulic drive system is strong enough to handle the hard soil here, and the machine has demonstrated impressive durability even under these harsh conditions.”

Customer 4 Profile:

Company: Southeast Asian Agricultural Group, Vietnam

Customer Review:

“Our farm in Vietnam has heavy clay and rocky soil, making stone removal crucial before planting. The CT-2100 has been a reliable workhorse in our operations. The 60 liters/minute hydraulic oil flow ensures it works perfectly with our tractors. It has saved us countless hours compared to manual stone picking, and the 2.5-meter working width allows us to cover a large area efficiently.” “The cubic meter hopper capacity means we can work for extended periods without frequent unloading. We are very satisfied with the performance of this machine and will continue to use it for land preparation work.”

8. EVER-POWER Factory Capabilities & OEM Customization

We understand that soil conditions vary not only from country to country but also within different regions of the same country.

Our manufacturing facilities are equipped with advanced CNC machining equipment and robotic welding production lines, enabling us to provide exceptional customized services.

Unlike traditional fixed assembly lines, we can adjust the chassis reinforcement, tooth spacing, and hydraulic line layout of our rock rakes to suit specific regional needs, such as adapting to the heavy clay soils common in Southeast Asia or the dry, abrasive soils of the Middle East.

We offer OEM services to our distributors and can customize the connection system to suit specific tractors.

Whether you need a rock rake configuration for road construction or specialized equipment for agricultural production, our engineering team is ready to assist you.

9. About us

– Rock & Soil Equipment: Rock rakes, rock pickers, rotavators, rotary cultivators

– Potato-Specific Machinery: Potato planters, potato furrowers, potato diggers (2-row, trailed, 2-row trailed, 4-row trailed), potato harvesters (2-row, big-bag compatible), potato processing auxiliary equipment

– Livestock Machinery: Specialized equipment for livestock farming operations

– Agricultural Inputs: High-performance fertilizers

10. Replaceable parts

10.1. PTO Drive Shaft and PTO Gearbox

1. PTO Shaft

2. Agricultural Gearboxes / PTO Gearboxes

10.2. Agricultural Gearboxes (including various applications)

1. Rotary tiller gearboxes

2. Fertilizer spreader gearboxes

3. Rake & mower PTO gearboxes

10.3. Hydraulic Cylinders

1. Standard hydraulic cylinders

2. Custom hydraulic cylinders

10.4. Drive Chains / Sprockets / Couplings / Gear Components

1. Roller Chains

2. Chains & Sprockets

3. Couplings

11. Frequently Asked Questions (FAQ)

Q1. Which tractor horsepower is strictly required to operate the CT-2100 rock picker efficiently in South Korean mountainous terrain?

A1. To handle the steep gradients and heavy granite soils typical of South Korea, we strictly recommend a tractor with a minimum engine power of 110 cv (HP) to ensure the hydraulic pump maintains the required 60 L/min flow rate for optimal picking performance.

Q2. How does the CT-2100 compare to a standard rock rake for skid steer when clearing construction sites?

A2. While a rock rake for skid steer is excellent for maneuvering in tight construction zones, the CT-2100 offers significantly higher capacity (2.5 m³) and speed for large-scale clearing, making it the superior choice for open-field reclamation where volume and speed are critical factors.

Q3. Can I use the CT-2100 rock picker in wet soil conditions, or should I wait for the ground to dry?

A3. It is highly advisable to operate the machine in dry conditions; wet, sticky soil can clog the screening grate, preventing soil from sifting back to the ground, which results in valuable topsoil being removed along with the stones.

Q4. Where can I find a reliable supplier for replacement tines and maintenance parts for the Watanabe CT-2100?

A4. We provide a full inventory of OEM replacement parts, including heat-treated alloy tines and hydraulic seals; simply contact our support team via the “Get a Quote” button, and we can ship directly to your location in South Korea or worldwide.

Q5. What is the estimated price quote for a fully customized rock picking solution including shipping to Incheon port?

A5. The final cost depends on customization options and current shipping rates; please submit an inquiry with your specific location and configuration requirements so our sales engineers can generate a precise, competitive commercial invoice for you.

Q6. Is it necessary to pre-process the field with a landscape rake or power rock rake before using the CT-2100?

A6. While not strictly mandatory, using a power rock rake to windrow stones first significantly increases the efficiency of the CT-2100, allowing it to collect more stones in fewer passes, thereby reducing fuel consumption and soil compaction.

Q7. How does the hydraulic drive system of the CT-2100 minimize maintenance costs compared to mechanical chain-driven pickers?

A7. The hydraulic drive system eliminates many moving parts found in mechanical chain drives, such as sprockets and tensioners, which are prone to wear and breakage from stone jams, thus significantly lowering long-term maintenance costs and downtime.

Q8. Is the CT-2100 suitable for use in rocky mountainous areas?

A8: Yes, the CT-2100 is very suitable for use in rocky mountainous areas, especially in regions like Gangwon-do, South Korea. The equipment is equipped with a powerful hydraulic drive system that can effectively clear hard rocks and maintain high performance even in soils rich in granite or basalt. With its high-strength picking claws and a large 2.5 m³ stone collection bin, it ensures smooth operation and reduces downtime even under the most challenging conditions.

Q9. What type of tractor is required for the CT-2100?

A9: The CT-2100 requires a tractor with at least 110 CV (horsepower) to power its hydraulic system and ensure a 60 L/min oil flow rate for optimal rock picking performance. The equipment uses a Category 2 three-point hitch system, making it compatible with medium to large agricultural tractors. To ensure the stability and efficient operation of the equipment, it is recommended to choose a tractor that can provide sufficient PTO and hydraulic output.

Q10. Is the CT-2100 suitable for use in wet soil?

A10: The CT-2100 is not recommended for use in wet or slippery soil conditions. Wet soil can cause the screen to clog, affecting soil return and potentially removing valuable topsoil along with the rocks, leading to soil loss. For optimal performance, it is recommended to operate in dry conditions to ensure soil integrity and efficient rock removal.

Editor: PXY

*Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.