A: Transforming Rock into Resource

1. Summary

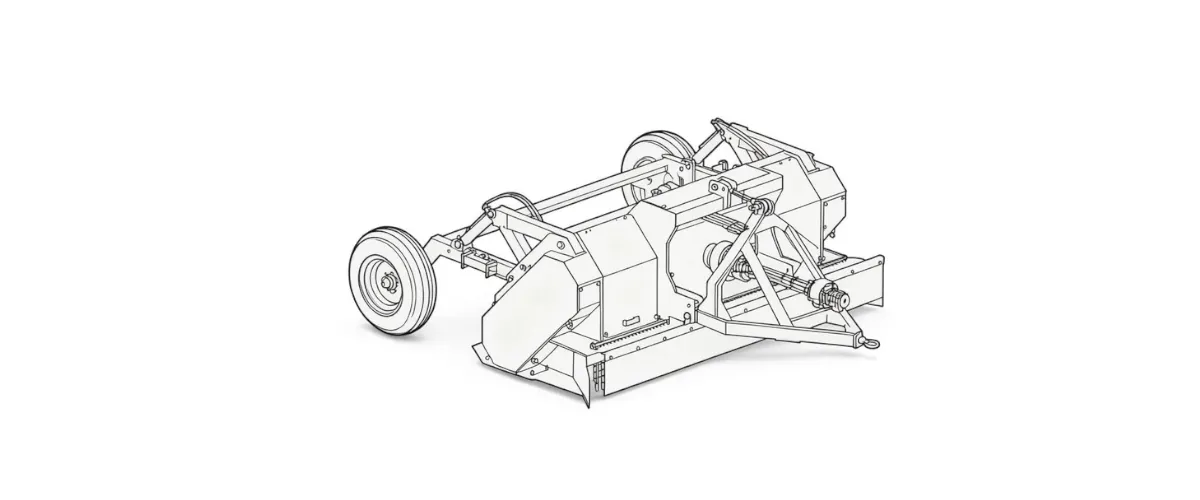

A PTO Stone Crusher is a heavy-duty agricultural implement designed to pulverize surface and subterranean rocks, converting them into sand or small aggregate to reclaim non-arable land. Utilizing high-speed tungsten carbide hammers and a steel chamber, machines like the EP-THOR Series can process stones up to 50cm in diameter, returning vital minerals to the soil. This technology is the superior alternative to stone picking for massive land clearing projects, road construction, and forestry mulching.

2. Five Key Facts

2.1. Destruction: Pulverizes rocks up to 50cm in diameter.

2.2. Power: Requires 180 – 230 CV PTO Power.

2.3. Soil Health: Improves drainage & mineralization.

2.4. Dual Use: Agriculture & Forestry/Roads.

2.5. Durability: Chassis & Carbide Tips.

3. The Mechanics of Lithic Reduction: How It Works

We first should look inside the crushing chamber. Unlike a Rock Rake, which merely moves stones aside, a PTO Stone Crusher (like the THOR Series) is a destructive engine. It is attached to the tractor’s 3-point hitch and driven by the Power Take-Off (PTO) shaft.

The heart of the machine is a massive steel rotor equipped with fixed tungsten-carbide hammers. As the tractor moves forward at a slow speed (0.3 – 2 km/h), the rotor spins against the direction of travel (or with it, depending on design). It strikes rocks and stumps with immense kinetic energy. These materials are thrown upward against a series of Counter-Knives lining the chassis ceiling. The rocks are shattered repeatedly in this “grinding zone” until the particles are small enough to pass through the rear grading grid. The result is a fine, uniform aggregate mixed into the topsoil.

4. Technical Specifications: THOR Series

*NOTE: The THOR series is engineered for the most demanding environments, from volcanic rock fields in Central America to limestone quarries in Europe. Below are the engineering parameters for our flagship models.

| Parameter | THOR 2.4 (Standard) | THOR 3.0 (Wide) |

|---|---|---|

| Working Width | 2.4 Meters | 3.0 Meters |

| Total Width | 2481 mm | 3000 mm |

| Total Length | 1546 mm | 1732 mm |

| Total Height | 1212 mm | 1212 mm |

| Machine Weight | 2300 Kg | 2800 Kg |

| Min. Tractor Power | 180 CV (HP) | 230 CV (HP) |

| Linkage Category | Cat 2 / Cat 3 | Cat 3 / Cat 4 |

| Working Speed | 0.5 – 3 km/h | 0.5 – 3 km/h |

| Hydraulic Valves | 2 Required | 2 Required |

| Max Stone Dia. | 30 – 40 cm | 40 – 50 cm |

5. Global Regulations: Safety & Environment

Operating heavy crushing machinery involves significant kinetic energy and dust generation. THOR Series ensures our equipment meets the diverse regulatory frameworks of our global client base.

- Safety Guarding (ISO 11684): Unlike rock rakes, crushers can eject debris at high velocity. Our units feature double-row safety chains and front guards, compliant with ISO 11684 safety signs and hazard pictorials standards essential for the USA and Europe.

- Noise & Vibration (EU Directive 2006/42/EC): For the European market, our rotors are dynamically balanced to minimize vibration, reducing operator fatigue and complying with the Machinery Directive regarding noise emission limits for agricultural forestry machinery.

- Brazil (NR-12): For the Brazilian market, the THOR series is fully adaptable to NR-12 standards. This includes mandatory shielding of the PTO shaft (cardan), specific safety colors, and emergency stop integration if required by the tractor setup.

- Dust Control (EPA/Local Environmental): In arid regions like Australia or the US Southwest, dust from stone crushing is a regulated pollutant. We recommend and can supply optional water spray kits to suppress silica dust, complying with OSHA silica standards for operator health.

6. Strategic Analysis: Stone Crusher vs. Rock Picker

💪 Strengths (Crusher)

- Zero Disposal: No need to truck tons of rocks out of the field; they disappear into the soil.

- Soil Improvement: Crushed rock releases minerals and improves soil porosity/drainage.

- Single Pass: Often clears land in one slow pass, whereas picking requires multiple passes.

📉 Weaknesses (Crusher)

- High Power: Requires very high horsepower tractors (180hp+) and creeper gears.

- Wear Parts: Hammers are consumables; operating costs are higher than simple raking in abrasive soils.

🚀 Opportunities

- Road Building: Can be hired out for municipal gravel road maintenance, creating a secondary revenue stream.

- Vineyard Prep: Ideal for creating deep, rock-free root zones for high-value crops like grapes and olives.

⚠️ Threats

- Fuel Costs: High energy consumption makes it sensitive to diesel price spikes.

- Hidden Metal: Subsurface scrap metal can cause catastrophic damage to the rotor (Ever Power offers slip-clutch protection).

7. Market Trends: The Rise of “In-Situ” Reclamation

The global agricultural trend is shifting from “clearing” to “transforming.” In the past, farmers physically removed rocks, creating massive piles that took up arable land. Today, the trend is situ soil Renovation.

Data indicates a 25% year-over-year increase in demand for PTO crushers in the forestry sector. They are being used to crush stumps and rocks simultaneously to create firebreaks. Additionally, the construction industry is adopting these agricultural units for Green Road Building, recycling existing roadbed material instead of trucking in new gravel.

8. Application Scenarios

1. Application In Agricultural Tractors

Agricultural tractors are the core equipment used in conjunction with stone crushers. The tractor drives the crusher through its PTO (Power Take-Off), enabling the crushing of stones and clearing of fields, farms, and construction sites.

2. Application In Crawler Bulldozers

Crawler bulldozers are widely used in large-scale earthworks and land preparation tasks. Their powerful engines help move stone crushers to perform heavy-duty operations such as land leveling and stone clearing.

5. Application In Dump Trucks

Dump trucks are commonly used to transport large stones and crushed materials. After being broken down by a stone crusher, the materials become smaller and more manageable, making them easier to transport using dump trucks.

7. Application In Cement Mixers

Cement mixers are used to mix crushed stones with cement to create concrete. The stone crusher supplies high-quality crushed material, ensuring the concrete produced is suitable for large construction projects.

8. Application In Large Road Construction Equipment

This category includes road milling machines, pavers, and other equipment used in road construction. Stone crushers act as material preparation devices, ensuring crushed stone is available for paving and other roadwork tasks.

9. Application In Small-Scale Mining Equipment

In mining operations, large stone crushers are used to break down ores, making them easier to extract and process. These devices are often used alongside stone crushers to handle large-scale ore clearing and preparation.

10. Application In Stone Screening Equipment

Stone screening equipment is used to sort crushed stone by size. When paired with stone crushers, it ensures that the crushed materials are properly sized to meet specific construction and agricultural project requirements.

9. Factory Customization & Compatibility

We understand that basalt in Idaho behaves differently from limestone in France. We offer bespoke engineering services to match the THOR crusher to your specific reality.

| Component | Standard | Watanabe Custom Option |

|---|---|---|

| Rotor Hammers | Fixed Carbide | Quick-Change Forestry Flails or Heavy-Duty Rock Teeth |

| PTO Speed | 1000 RPM | 540 RPM Gearbox (for older tractors) |

| Rear Roller | Hydraulic Bar | Packer Roller for Road Compaction |

| Hitch | Cat 2 | Cat 3 / 4 Heavy Duty or Quick-Hitch |

10. Customer Success Case: Vineyard Reclamation in Rio Grande do Sul

“Since we started using their PTO rock crusher on our farm, it’s really saved us a ton of effort! Before, we had to manually clear stones from the fields every year—not only was it a huge workload, but it was also incredibly inefficient. Now with this machine, powered by the tractor, it’s so much easier, guys.”

— A farmer from the American Midwest

As a company engaged in both agriculture and construction, we handle large volumes of crushed stone. This crusher performs exceptionally well—not only does it efficiently break down large rocks, but it also integrates seamlessly with tractors, streamlining the entire process. Even during winter, the machine operates reliably, which is incredibly convenient!

— Manager, Canadian Construction and Agriculture Company

We use the PTO stone crusher to process rocks on rural roads, and the machine’s power and performance exceeded our expectations. When connected to a tractor, it operates smoothly and is easy to handle—highly recommended.

— Rural Road Construction Company, UK

As a business that combines agriculture with small-scale mining, we handle large volumes of crushed stone. The crusher has been a tremendous help—it’s perfectly suited for our diverse operational needs. It’s efficient and durable, making it a worthwhile investment for both farming and mining operations.

— Owner, Brazilian Mining and Agricultural Company

Honestly, this machine is a real lifesaver for us. The land we used to work had lots of rocks, and we always had to clear them by hand—it was time-consuming and backbreaking. Now it’s different. I’ve got a machine doing the work for me, ha ha ha ha. It’s super easy to operate and perfect for agricultural businesses like ours.

— Mexican Business Owner

11. Replacement components:

Like any agricultural machine, certain parts of the AWB-1600 are subject to regular wear. The digging blades, chains, and hydraulic components may need replacement after extensive use. Timely replacement of these parts ensures that the machine maintains its efficiency and doesn’t cause unnecessary delays during harvest.

Gearbox

PTO Shaft (Power Take-Off Shaft)

Transmission System

These core components are meticulously designed and manufactured to ensure the stone crusher performs exceptionally well, maintaining high efficiency and stability even in challenging agricultural environments.

11. Frequently Asked Questions (FAQ)

Q1: How does a PTO stone crusher work?

A1: A PTO stone crusher works by connecting to a tractor’s PTO shaft. The tractor’s engine powers the crusher, allowing it to break down large stones into smaller, more manageable pieces. The machine’s crushing mechanism typically includes rotating hammers or blades that grind the stones as they are fed into the machine.

Q2:What is the difference between a rock rake and a stone crusher?

A2 rock rake (like our EW-4000) windrows stones to the side for collection. It leaves the field empty of rocks but requires a secondary operation to remove the piles. A stone crusher (like the THOR) pulverizes the rocks right where they lie, turning them into soil/sand. This eliminates disposal costs but requires a much more powerful tractor.

Q3: How much horsepower do I need to run a 2.4m stone crusher?

A3: Stone crushing is energy-intensive. For the Ever Power THOR 2.4 model, a tractor with a minimum of 180 CV (Horsepower) is required. Crucially, the tractor must have a “creeper” gear or IVT transmission to maintain speeds as low as 0.3 km/h while keeping the PTO at full RPM.

Q4: Can a stone crusher be used for maintaining rural gravel roads?

A4: Yes, PTO stone crushers are excellent for road maintenance. They can grind existing potholes and large protruding stones into a uniform aggregate mix. When compacted, this creates a smooth, durable surface that is far superior to simply grading loose gravel.

Q5: How deep can the THOR series crusher work?

A5: The THOR series is designed to work primarily on the surface and sub-surface, typically reaching depths of 15 to 25 cm. This is ideal for agricultural seedbed preparation and forestry mulching. Deeper working depths would require specialized “soil stabilizer” machines.

Q6: How long do the carbide hammers last?

A6: Lifespan varies greatly by rock abrasiveness. In soft limestone, hammers may last 500+ hours. In abrasive granite or quartzite, they may need replacement after 150-200 hours. Ever Power uses premium tungsten carbide to maximize lifespan, and the hammers are bolt-on for easy field replacement.

Q7: What types of stones can the PTO stone crusher handle?

A7: The PTO stone crusher is designed to handle a variety of stones and rocks commonly found in agricultural fields, including small to medium-sized rocks, gravel, and other debris. It can crush stones of different hardness levels, making it versatile for use in various land-clearing applications.

Q8: How much maintenance does a PTO stone crusher require?

A8: Regular maintenance is crucial for ensuring the long-term performance of a PTO stone crusher. Maintenance tasks include lubricating moving parts, checking for wear on the crushing mechanism, cleaning the machine after use, and inspecting the PTO connection. It’s important to follow the manufacturer’s maintenance guidelines to prevent downtime and costly repairs.

Q9: Can a PTO stone crusher be used in rocky terrains?

A9: Yes, a PTO stone crusher is specifically designed to work in rocky terrains where land preparation is difficult due to large stones. It is highly effective in clearing stones from fields, road construction projects, and other areas with rough terrain, making them more suitable for farming or construction.

Q10: Are PTO stone crushers available for sale?

A10: Yes, PTO stone crushers are available for sale from various manufacturers, including trusted brands like New Holland, Hesston, and Watanabe. You can find a wide range of models based on size, power requirements, and specific functionality suited to different agricultural and land-clearing tasks.

*Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.

Ready to reclaim your land? Contact [email protected] for a quote.

Editor: PXY