Beschrijving

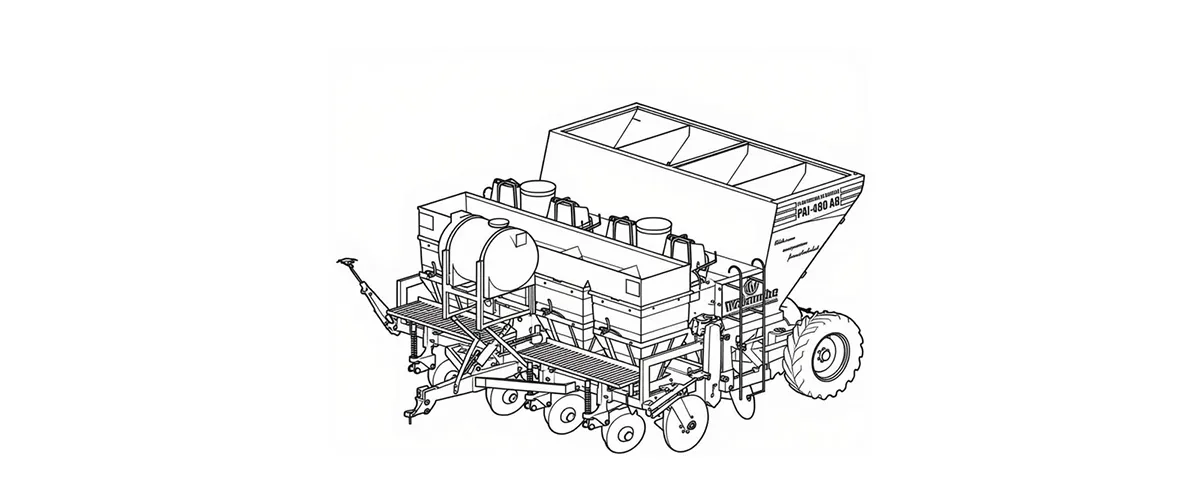

1. PAI-480 – AR-4 ROWS Technical Engineering Data

| Specification Parameter | Performance Detail (PAI-480-AR) |

|---|---|

| Rows Configuration | 4 ROWS |

| Empty Structural Weight | 2300 Kg |

| Seed Bunker Capacity | 4000 Kg |

| Fertilizer Capacity (Primary) | 2000 Kg |

| Fertilizer Capacity (Secondary) | 500 Kg |

| Insecticide Tank Option | 300 L or 600 L |

| Min. Tractor Power Required | 140 cv |

| Operational Working Speed | 4 – 8 km/h |

| Distribution System | 16-Combination Gearbox |

2. Five Key Facts: PAI-480 – AR Series

- Unrivaled Load Capacity: Boasts a 4,000 Kg seed bunker and a combined 2,500 Kg fertilizer capacity, minimizing downtime for refilling during peak planting windows.

- Integrated Chemical Management: Features a versatile insecticide tank (300 L to 600 L options) to provide immediate protection to seeds at the moment of soil contact.

- Variable Speed Precision: Operates at an optimal working speed of 4-8 km/h, balancing rapid field coverage with surgical seed placement accuracy.

- Mechanical Gearbox Sophistication: The 16-combination distribution gearbox ensures that seed density is perfectly matched to specific soil conditions and moisture levels.

- Heavy-Duty Chassis: At a structural weight of 2,300 Kg (empty), the machine provides the necessary downward force for consistent furrow depth in compacted or reclaimed soils.

3. Industrial Value Proposition: Maximizing ROI Potato Hubs

The PAI-480 – AR represents a seismic shift in agricultural productivity in the commercial potato sector. In provinces like PyeongChang and Gangwon-do, where labor costs are rising and planting windows are narrowing due to unpredictable climate shifts, the ability to automate the entire planting cycle is paramount. This potato planter machine tractor integration goes far beyond basic seeding; it consolidates seed drilling, multi-stage fertilization, and chemical spraying into one seamless tractor operation. By utilizing the PAI-480 – AR, large-scale cooperatives can reduce their labor dependency by up to 70% compared to traditional hand potato planter methods or smaller 2-row configurations. The machine is built with high-resistance structural steel, ensuring it can withstand the torsional stresses of operating in the sloped terrains typical of the Korean peninsula.

4. Legal Compliance and Global Land Management Standards

Operating heavy agricultural machinery like the PAI-480 – AR in South Korea mandates strict adherence to the Agricultural Mechanization Promotion Act, which ensures that all 4-row commercial potato planter units meet specific safety and emission standards for tractor-mounted implements. Furthermore, land management in Korea is heavily governed by soil conservation protocols designed to prevent erosion in mountainous farming zones. The PAI-480 – AR is engineered to meet these requirements by maintaining structural soil integrity through controlled furrowing depths. Globally, this equipment aligns with ISO 4254-1 safety standards for agricultural machinery, particularly regarding the shielding of rotating parts and hydraulic pressure safety. In regions where rotshark implements are used for land reclamation before planting, local laws (such as those in the EU or Australia) often require that stone removal and deep tilling do not adversely affect the water table or cause topsoil instability. Watanabe’s precision metering for both fertilizer and insecticide also supports “Integrated Pest Management” (IPM) regulations, ensuring that chemical application is localized to the seed zone, thereby preventing hazardous runoff into local groundwater systems, a critical compliance factor for ESG-conscious farming operations worldwide.

5. Tractor Compatibility and Application Scenarios

| Compatible Brand | Typical Series/Models | Linkage Standard |

|---|---|---|

| LS Mtron | XP Series / MT7 Series (140hp+) | Category 2 / 3N |

| TYM / Daedong | T130 / PX Series | Category 2 |

| Kubota | M7 Series / M8 Series | Universal ISO Cat 2 |

| John Deere | 6M Series / 6R Series | Standard Cat 2/3 |

6. Application Scenarios

South Korea – Precision Farming in Gangwon-do (Sloped Terrains)

Application: The PAI-480 – AR 4-row potato planter is ideal for the sloped, rocky terrains typical of Gangwon-do. Its heavy-duty design (2,300 Kg) ensures consistent planting depth even on steep hillsides, making it perfect for regions with irregular topography. The integrated insecticide tank (300 L) ensures immediate protection for seeds, a crucial benefit for managing pest control in challenging terrains.

Benefit: Reduces labor costs and operational downtime while maintaining planting accuracy in difficult landscapes.

United States – Large-Scale Potato Farming in Idaho

Application: In Idaho, one of the largest potato-producing regions in the U.S., the PAI-480 – AR 4-row model with its 4,000 Kg seed capacity is used for large-scale planting. The advanced 16-combination gearbox allows farmers to adjust seed spacing for different potato varieties, optimizing planting in various soil conditions.

Benefit: Increases planting efficiency, saves time, and reduces labor costs on large fields while ensuring uniform seed placement.

Australia – Commercial Potato Farming in the Murray-Darling Basin

Application: The PAI-480 – AR is used in the water-scarce regions of the Murray-Darling Basin in Australia, where water and fertilizer conservation is a key concern. With its large fertilizer tank capacity (2,000 Kg), the planter ensures precision fertilizer placement, minimizing runoff and conserving water.

Benefit: Improves resource efficiency, reduces environmental impact, and complies with Australia’s strict agricultural sustainability standards.

Canada – Potato Farming in the Prairie Provinces

Application: The PAI-480 – AR is deployed across Canada’s vast prairies, where large fields are common. Its high seed bunker capacity of 4,000 Kg and fertilizer capacity of 2,000 Kg allows for minimal downtime, helping farmers plant across hundreds of hectares with fewer refills. The planter’s 4-8 km/h working speed makes it perfect for large-scale operations.

Benefit: Maximizes efficiency on large farms and reduces operational interruptions during planting season.

United Kingdom – Commercial Farming in Scotland’s Highlands

Application: In the Scottish Highlands, where terrain can be challenging, the PAI-480 – AR’s heavy build and precise seed placement features make it ideal for planting in damp, rocky, or uneven fields. The fertilizer and insecticide integration ensures that crops receive proper treatment during planting.

Benefit: Ensures consistent planting depth and seed protection even in adverse conditions, improving crop yields.

India – Mechanized Farming in Punjab

Application: The PAI-480 – AR supports large potato farming operations in Punjab, India, where mechanization is rapidly growing. The planter’s ability to fertilize and plant simultaneously helps farmers save time during the planting season, which is crucial during the monsoon season.

Benefit: Increases operational efficiency, reduces manual labor, and ensures the uniformity of crop production across diverse soil types.

Brazil – Large-Scale Potato Farming in São Paulo

Application: In Brazil, where mechanized farming is expanding rapidly, the PAI-480 – AR 4-row planter fits the need for efficient and high-capacity equipment. With its 4,000 Kg seed bunker and high-speed operation, it is used to plant vast potato fields in São Paulo’s fertile lands.

Benefit: Increases productivity and reduces operational costs, meeting the growing demand for potatoes in Brazil’s expanding agricultural market.

7. Market Trend Analysis:

The global agricultural machinery landscape is rapidly moving toward “Consolidated Multifunctionality.” In markets like South Korea, we are seeing a 15% annual increase in the demand for planters that can handle multiple soil treatments simultaneously. The PAI-480 – AR is perfectly positioned for this trend, as it eliminates the need for separate fertilization and spraying passes, which reduces soil compaction and fuel consumption—two critical KPIs for modern sustainable farming. Furthermore, as the industry moves toward “Smart Farming 4.0,” there is an increasing reliance on high-precision mechanical gearboxes rather than older hydraulic drives, as they offer more reliable seed distribution in extreme soil moisture conditions. High-capacity 4-row units are becoming the standard for commercial ventures, as they provide the scale necessary to remain competitive against imported tubers. Watanabe’s focus on integrated chemical application is also a response to the global tightening of environmental regulations, as it ensures that insecticide is used only where absolutely necessary—at the root zone—rather than broadcast across the entire field.

8. Customer Success Case:

Client 1 Profile: United States, Idaho Potato Grower

Customer Reviews:

“As one of the largest potato producers in Idaho, speed and accuracy are everything. The PAI-480 – AR’s 4-row setup and high seed bunker capacity have helped us plant more land in a shorter amount of time. The ability to adjust seed spacing with the 16-combination gearbox makes it easy to cater to different potato varieties. It has made our operations far more efficient and we’re seeing a significant reduction in labor costs.”

Client 2 Profile: Australia, Murray-Darling Basin Commercial Farmer

Customer Reviews:

“In Australia’s dry regions, conserving water is crucial, and the PAI-480 – AR has made that possible. The precision fertilization and integrated insecticide system ensure minimal chemical runoff, which is a priority in our area. The sturdy design easily handles our tough soil, and we’ve noticed better soil health and higher yields since we switched from older models.”

Client 3 Profile: Canada, Prairie Provinces Potato Farmer

Customer Reviews:

“On our large potato fields in Canada, efficiency is key, and the PAI-480 – AR has exceeded our expectations. The 4-row system lets us cover more ground without sacrificing seed accuracy. The machine’s robust frame ensures it can handle the heavy-duty tasks needed in our tough soil conditions. The precise metering system for both fertilizers and insecticides has made a noticeable difference in our crop yields.”

Client 4 Profile: Russia, Siberian Potato Farmer

Customer Reviews:

“Farming in Siberia isn’t easy, but the PAI-480 – AR has been the perfect fit for our large fields. The machine’s weight distribution helps keep it stable on our rocky and uneven terrain. With its 4,000 Kg seed capacity, we can plant vast areas with fewer refills, and the integrated chemical application is a huge bonus. It’s been great for handling our harsh conditions while keeping our planting operations smooth.”

Client 5 Profile: Brazil, São Paulo Potato Farm

Customer Reviews:

“The PAI-480 – AR has drastically improved our potato planting operations in São Paulo. The high-capacity seed bunker and fertilizer tank allow us to cover more land efficiently, saving both time and fuel. The precision planting and adjustable seed spacing have made a significant difference in our potato quality. With the flexibility of the 16-combination gearbox, we can cater to different soil conditions, which is crucial for maintaining productivity.”

9. EVER-POWER Factory Capabilities & OEM Customization

We understand that soil conditions vary not only from country to country but also within different regions of the same country.

Our manufacturing facilities are equipped with advanced CNC machining equipment and robotic welding production lines, enabling us to provide exceptional customized services.

Unlike traditional fixed assembly lines, we can adjust the chassis reinforcement, tooth spacing, and hydraulic line layout of our rock rakes to suit specific regional needs, such as adapting to the heavy clay soils common in Southeast Asia or the dry, abrasive soils of the Middle East.

We offer OEM services to our distributors and can customize the connection system to suit specific tractors.

Whether you need a rock rake configuration for road construction or specialized equipment for agricultural production, our engineering team is ready to assist you.

10. About us

– Rock & Soil Equipment: Rock rakes, rock pickers, rotavators, rotary cultivators

– Potato-Specific Machinery: Potato planters, potato furrowers, potato diggers (2-row, trailed, 2-row trailed, 4-row trailed), potato harvesters (2-row, big-bag compatible), potato processing auxiliary equipment

– Livestock Machinery: Specialized equipment for livestock farming operations

– Agricultural Inputs: High-performance fertilizers

11. Replaceable parts

11.1. PTO Drive Shaft and PTO Gearbox

1. PTO Shaft

2. Agricultural Gearboxes / PTO Gearboxes

11.2. Agricultural Gearboxes (including various applications)

1. Rotary tiller gearboxes

2. Fertilizer spreader gearboxes

3. Rake & mower PTO gearboxes

11.3. Hydraulic Cylinders

1. Standard hydraulic cylinders

2. Custom hydraulic cylinders

11.4. Drive Chains / Sprockets / Couplings / Gear Components

1. Roller Chains

2. Chains & Sprockets

3. Couplings

12. Commercial Seeding FAQ

Q1. What is the typical commercial potato planter cost for high-capacity machines like the Watanabe PAI-480 – AR in South Korea?

A1. The pricing for a PAI-480 – AR depends on your chosen tank configuration and customization needs; however, it offers a superior ROI for commercial plots over 50 hectares. For a detailed quote including shipping to Busan or Incheon, please click our ‘Get a Quote’ button to speak with a supplier.

Q2. Where can I find a reliable potato planter machine tractor supplier in Gyeonggi-do that offers local maintenance and spare parts?

A2. Watanabe equipment is supplied through an authorized network that covers all major agricultural provinces, including Gyeonggi-do. We provide full technical support, 16-combination gearbox calibrations, and genuine replacement parts to ensure your 4-row commercial planter stays operational during the critical spring planting window.

Q3. How does the seed bunker capacity of 4,000 Kg on the PAI-480 – AR compare to smaller planters?

A3. The 4,000 Kg capacity is nearly four times larger than our standard PAI-2100 models, allowing for industrial-scale coverage without constant stopping[cite: 95, 106]. This high payload is designed specifically for tractors with at least 140 cv power, enabling you to plant larger areas in much shorter time frames.

Q4. Which 3 point potato planter model is best suited for the sloped fields found in the Gangwon-do region?

A4. For heavy-duty commercial operations on sloped terrain, the PAI-480 – AR is ideal because its 2,300 Kg structural weight provides the necessary stability and downward pressure[cite: 106]. The Category 2 linkage ensures a secure connection, preventing the machine from swaying or losing furrow depth consistency on steep grades.

Q5. Can the 16-combination gearbox in the Watanabe planter be used with different seed potato sizes for custom density?

A5. Yes, the gearbox is specifically designed for versatility, allowing for 16 different distribution combinations[cite: 85]. This allows you to precisely calibrate the spacing between each seed based on the specific variety and the nutrient density of your soil, which is critical for maximizing final harvest tonnage.

Q6. Is it better to buy a new PAI-480 – AR or look for a used potato equipment for sale?

A6. While a used potato equipment for sale listing might seem cheaper initially, the PAI-480 – AR includes modern integrated spraying and dual-fertilizer systems that older models lack[cite: 106]. A new unit also guarantees that the gearbox and 4000 Kg bunker are free from fatigue, providing a much longer operational lifespan.

Q7. What are the specific hydraulic valve requirements for operating the insecticide tank and fertilizer system on a 4-row planter?

A7. To operate the full functionality of the PAI-480 – AR, your tractor should be equipped with a minimum of 2 remote control valves and a high-flow hydraulic pump. This ensures that both the fertilizer distribution and the insecticide sprayer maintain consistent pressure while the machine is traveling at operational speeds of 4-8 km/h.

Editor: PXY

*Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.