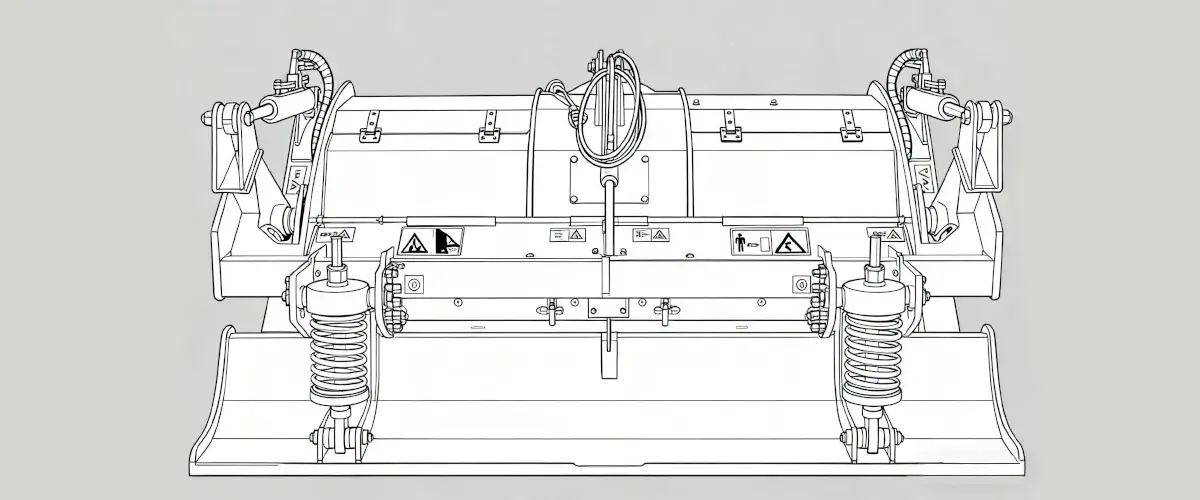

EP-PTO STONE CRUSHER PSC MODELS

The PTO STONE CRUSHER PSC MODELS is a lightweight series crusher produced by our company. The product is compact and lightweight, making it extremely versatile. For example, it is particularly suitable for stone ground treatment in narrow areas such as rural roads and driveway maintenance, farms, and pasture renovation. After the machine passes, the bulldozer component helps maintain a level surface.

1. Technical Specifications of PTO STONE CRUSHER PSC Models

| PTO STONE CRUSHER PSC Models | PSC 100 | PSC125 | PSC150 | PSC 175 | PSC 175 | PSC 200 |

|---|---|---|---|---|---|---|

| Tractor (hp) | 70-120* | 80-120* | 90-120* | 100-120* | 100-150 | 120-150 |

| PTO (rpm) | 540-1000 | 540-1000 | 540-1000 | 540-1000 | 1000 | 1000 |

| Working width (mm) | 1110 | 1350 | 1590 | 1830 | 1830 | 2070 |

| Total width (mm) | 1414 | 1654 | 1894 | 2134 | 2134 | 2374 |

| Weight (kg) | 1230 | 1280 | 1440 | 1570 | 1600 | 1750 |

| Rotor diameter (mm) | 450 | 450 | 450 | 450 | 450 | 450 |

| Max shredding diameter (mm) | 150 | 150 | 150 | 150 | 150 | 150 |

| Max working depth (mm) | 150 | 150 | 150 | 150 | 150 | 150 |

2. Advanced Solutions for Agricultural PTO STONE CRUSHER PSC Models in Korea

The PSC Series Field Stone Crusher is a purpose-engineered, machine-crafted for land clearing, agricultural site preparation, and rural infrastructure maintenance. Engineered for exceptional durability and consistent performance, the PSC Series efficiently reduces field stones, rocks, and surface debris into smaller, manageable fragments—boasting a maximum shredding diameter of 150mm—making it the ideal solution for pasture renovation, road base preparation, and crop field leveling.

As a trusted manufacturer of the PSC Series Field Stone Crusher, we prioritize streamlined, robust construction that minimizes downtime and maximizes operational productivity. Compatible with standard tractor PTOs, it integrates seamlessly into existing farm or land management workflows, eliminating the need for specialized auxiliary equipment. For farmers, ranchers, and land contractors, the agricultural-focused PSC Series Field Stone Crusher delivers a cost-efficient solution to mitigate soil damage caused by hidden stones, safeguard tillage implements, and enhance seedbed uniformity—directly supporting improved crop establishment and long-term farm productivity.

Municipalities and rural developers also depend on this unit for gravel road maintenance and site preparation: its consistent rock sizing optimizes compaction efficiency and drainage performance, ensuring durable, high-quality infrastructure outcomes. Whether you’re seeking a reliable PSC Series supplier, or exploring solutions such as “stone crusher for pasture renovation” or “heavy-duty crusher for rocky farmland,” our product delivers tangible value through proven engineering, easy serviceability, and industry-trusted reliability—designed to meet the rigorous demands of 2B industrial and agricultural applications.

3. Application of the PTO STONE CRUSHER PSC Models in Practical Scenarios

- Agricultural Field Preparation

The PSC Model efficiently crushes surface and shallow-buried stones before or during fallow periods, protecting tillage equipment (such as plows, harrows, and seeders) from damage and creating a more uniform seedbed for improved crop emergence.

- Rural Road & Driveway Maintenance

Ideal for on-site crushing and leveling of fieldstone to maintain or construct farm lanes, forest roads, and residential driveways. This reduces reliance on purchased aggregate and improves road stability and drainage.

- Construction Site Clearing

Supports small-scale land development by clearing surface rock during initial site preparation, enabling smoother grading, utility installation, and foundation work without costly rock removal or hauling.

- Erosion Control & Terracing

Crushed stone from the PSC Model can be repurposed to fill gullies or reinforce slopes, helping mitigate soil erosion on sloped terrain.

- Forestry & Firebreak Creation

Assists in creating and maintaining firebreaks or access trails in wooded areas by removing rock obstacles, facilitating equipment movement and vegetation management for wildfire prevention.

4. Product Features of the Field Stone Crusher STCL Model

The PSC Series Field Stone Crusher combines robust engineering, precise performance, and versatile adaptability to meet the demands of agricultural, rural infrastructure, and land management applications. Its core features are as follows:

- Durable & Protected Construction

Sealed Machine Body: Shields internal components from debris, extending service life.

Adjustable Fixed Blades: Controls crushed stone size (max 150mm) for uniform output, paired with welded fixed blades and steel fixed-blade flange shafts for heavy-duty durability.

Dual-Row Protection Chains & Internal Wear-Resistant Liners: Reduces wear from abrasive materials, minimizing maintenance costs.

- Precise Performance & Consistent Output

Max Working Depth**: 150mm, ideal for removing embedded stones while preserving topsoil.

Uniform Shredding**: Delivers consistent 150mm max fragment size—critical for pasture renovation, seedbed preparation, and road base compaction.

- Tractor Compatibility & Easy Integration

Tractor Power Range: Matches 70–150 hp tractors (model-dependent: e.g., PSC100 for 70–120 hp; PSC200 for 120–150 hp).

PTO Flexibility: Supports 540–1000 rpm (PSC models) or 1000 rpm (PSC models) via cam clutch-equipped PTO drive shafts and optional 540/1000 rpm gearboxes.

Adjustable 3-Point Hitch Extension: Perfectly adapts to various tractor types, enabling seamless workflow integration without specialized equipment.

- Versatile Design for Multiple Applications

Model-Specific Working Widths: Ranges from 1110mm (PSC-100) to 2070mm (PSC-200), fitting small pastures to large crop fields.

Optional Attachments: Extend functionality with scrapers (for road surfaces), leveling plates (for soil smoothing), and hydraulic top hitches to suit site-specific needs.

5. Practical Application Case of PTO STONE CRUSHER PSC Models

- Product Case:

PTO STONE CRUSHER PSC Models – Enabling Efficient Land Clearing for a Midwest Farming Operation

- Customer Profile

Location: Central Iowa, USA

Operation Type: Family-owned row-crop farm (corn and soybeans)

Land Challenge: 120-acre field recently converted from pasture; surface littered with stones ranging from 4 to 12 inches in diameter

- Challenge

After acquiring additional acreage, the farmer encountered frequent damage to his no-till planter and grain drill due to hidden fieldstones. Traditional rock picking was labor-intensive and only removed larger stones, leaving smaller fragments that still posed equipment risks. The operation needed a cost-effective, one-pass solution to process stones in place without removing topsoil or disrupting field productivity.

- Solution Implemented

The farm invested in a PTO STONE CRUSHER PSC Models, mounted to a 120 HP tractor via standard 540 RPM PTO. The unit was selected for its: Heavy-duty rotor with replaceable carbide-tipped hammers, Adjustable rear discharge door for controlled fragment size (target: ≤3 inches), Compatibility with existing farm equipment, Reputation as a reliable PTO STONE CRUSHER PSC Models for agriculture.

- Solution Implemented

Implementation Process Operated at 4–5 mph across the 120-acre field in early spring. Single pass crushed >90% of surface stones into manageable fragments .No soil inversion—preserving no-till principles and moisture retention.

- Results & Benefits

Improved seed placement consistency due to a smoother field surface.

Reduced the need for manual rock picking, freeing up 30+ labor hours

Customer Quote

“The PSC Model paid for itself in one season. We’re not just clearing rocks—we’re protecting our investment in modern planting technology.”

6. Chi siamo

Siamo un produttore professionale di frantoi per pietre con presa di forza orientato all'innovazione. Grazie a oltre 50 anni di esperienza nel settore e a una profonda comprensione delle esigenze dei clienti, forniamo soluzioni di frantumazione di alta qualità per utenti globali. Oltre alle attrezzature per la frantumazione del nocciolo, abbiamo anche creato un ecosistema di macchinari agricoli multi-settore per supportare l'intera filiera agricola:

I nostri stabilimenti produttivi sono in possesso di una serie completa di certificazioni essenziali per la produzione di macchinari agricoli, tra cui:

- Certificazione del sistema di gestione della qualità ISO 9001

- Certificazione di sicurezza dei macchinari CE (per il mercato UE)

- Certificazione di Grado A per l'Integrazione dell'Informatizzazione e dell'Industrializzazione

- Produttore verificato SGS

- E altre credenziali riconosciute dal settore

- Centri di lavoro CNC

- Sistemi di taglio laser e plasma

- Celle di saldatura robotizzate

- Linee di assemblaggio automatizzate

- Sistemi di trattamento termico e finitura superficiale

- Macchine di misura a coordinate (CMM) e strumenti di ispezione in linea

- Soluzioni software per fabbriche digitali e industriali

- Stazioni di prova dinamometriche

- Sistemi intelligenti di magazzinaggio e logistica

Questo ecosistema di prodotti one-stop ci consente di supportare l'intera filiera agricola dei nostri clienti, dalla preparazione del terreno alla raccolta delle colture e alla gestione del bestiame.

Scopri di più sulla nostra storia

7. I nostri servizi

Forniamo servizi completi e completi, dalla consulenza all'acquisto fino all'assistenza post-vendita: il nostro team di professionisti ti aiuta a selezionare i modelli con precisione, mentre il team post-vendita fornisce assistenza per l'installazione, supporto tecnico a lungo termine e fornitura di pezzi di ricambio originali per garantire il funzionamento stabile dell'apparecchiatura.

Interessato ai nostri prodotti e servizi? CONTATTACI