Beskriuwing

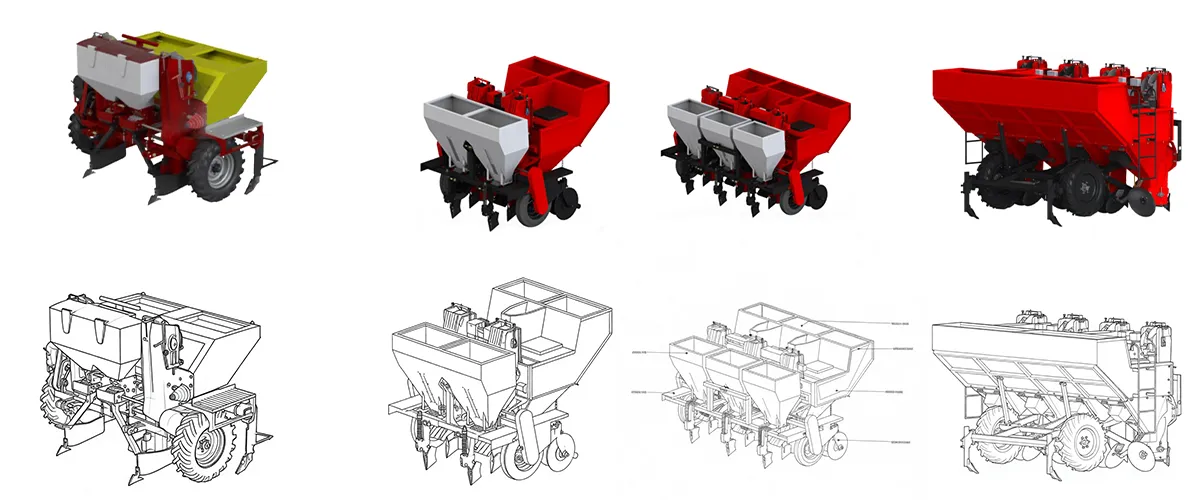

1. Detailed Technical Specifications

| Technical Feature | PAI-2100 (2 Rows) | PANTHER (2 Rows) | PANTHER (3 Rows) | PANTHER (4 Rows) |

|---|---|---|---|---|

| Empty Weight | 860 Kg | 1325 Kg | 1500 Kg | 1450 Kg |

| Min. Engine Power | 85 cv | 75 cv | 100 cv | 125 cv |

| Seed Capacity | 350 Kg | 700 Kg | 750 Kg | 1200 Kg |

| Fertilizer Cap. | 200 Kg | 680 Kg | 600 Kg | – |

| Insecticide Tank | 200L / 300L | Option Available | 300 L | – |

| Working Speed | 3-5~km/h | |||

2. FIVE KEY FACTS

- Unified Operation System: The PANTHER series consolidates soil preparation, seed drilling, fertilizer spreading, and spraying into one pass, significantly reducing labor costs in aging agricultural regions.

- Variable Spacing Gearbox: Equipped with a sophisticated 16-speed gearbox, allowing farmers to customize seed distribution according to specific potato varieties and soil richness.

- High Capacity Payload: The PANTHER 4-row model supports up to 1200 Kg of seed capacity and 600 Kg of fertilizer, maximizing uptime by reducing refill frequency.

- South Korea Terrain Ready: Specifically balanced with an empty weight of up to 1500 Kg (PANTHER 3-row) to ensure consistent planting depth even in the sloped fields of Gangwon-do.

- Tractor Synergy: Designed for minimum power requirements starting at 75 cv (PANTHER 2-row), making it compatible with widely used Korean tractor brands like LS Mtron and TYM.

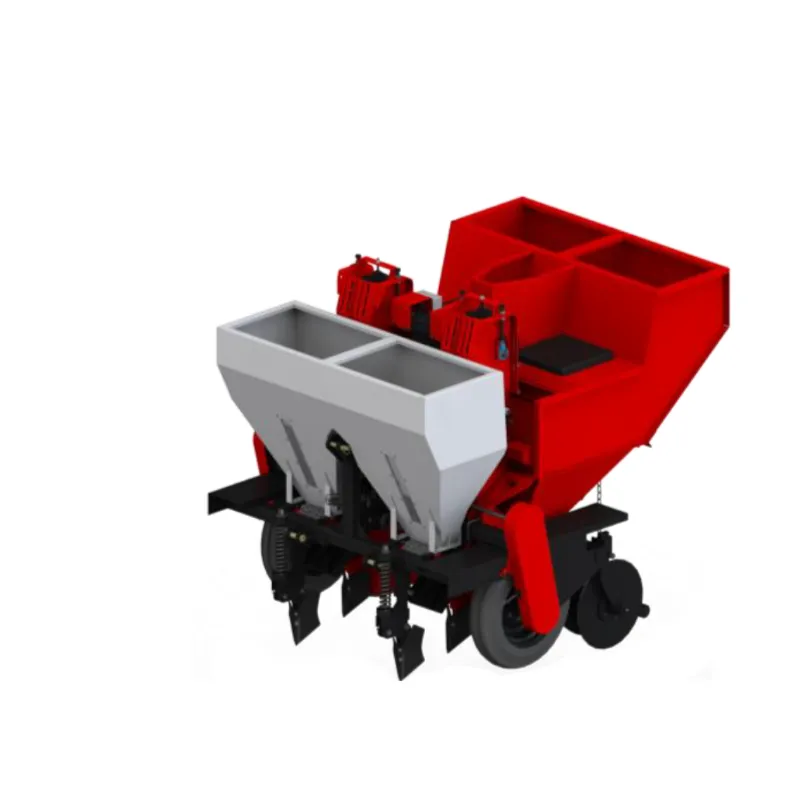

3. Watanabe Excellence: The Premier Choice for Commercial Potato Farming

Precision planting is the foundation of agricultural profitability.

The PAI-2100 and PANTHER series are engineered to replace inefficient hand potato planter methods and low-quality potato planter diy setups with a robust, industrial-grade solution. As agricultural labor becomes increasingly scarce in South Korea, the ability of a 3-point potato planter to automate the most demanding aspects of the crop cycle is invaluable.

By ensuring that each seed is placed at the exact depth and treated with a localized dose of fertilizer and insecticide, our machines promote uniform germination. This uniformity is critical for mechanical harvesting later in the season, as it prevents tuber damage and ensures a higher grade of market-ready potatoes. Unlike a vintage potato planter, the PANTHER series integrates modern hydraulic controls and high-tensile steel components to withstand high-torque operations in compacted or semi-rocky soils.

4. Replacement & Compatibility Standards

| Tractor Brand | Linkage Compatibility | Hydraulic Requirement | Compatibility Status |

|---|---|---|---|

| LS Mtron (XP/MT7) | Category 2 Standard | Min. $60~L/min$ | Perfect Match |

| Kubota (M Series) | ISO Cat 2 | Min. $55~L/min$ | Full Integration |

| John Deere (6M/6R) | Category 2/3N | Min. $65~L/min$ | Seamless Support |

| TYM (T130) | Category 2 Standard | Min. $60~L/min$ | Perfect Match |

*Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.

5. Selection & Installation Guide for Modern Planters

How to Choose the Right Model

Selecting a potato planter machine tractor unit depends on three primary factors: farm scale, terrain slope, and tractor HP. For medium-sized family farms in Gyeonggi-do, the PAI-2100 offers the best balance of weight and efficiency. For large-scale industrial farming in Gangwon-do, the PANTHER 4-row model provides the volume necessary to cover hundreds of hectares quickly. Always verify your tractor’s hydraulic flow exceeds $60~L/min$ to ensure consistent spraying and gear engagement.

Basic Installation Steps (How-To)

- Connect the 3 point potato planter linkage to the tractor’s Category 2 arms and secure with locking pins.

- Attach the PTO cardan shaft to the planter’s input, ensuring the safety chains are fastened.

- Calibrate the 16-speed gearbox according to the desired seed spacing (check the Watanabe reference chart).

- Fill the fertilizer and seed bunkers, then test the hydraulic spraying system for blockages.

6. Laws and regulations: Soil Stability & Land Management

Operating a heavy potato planter for sale in South Korea requires compliance with the Agricultural Mechanization Promotion Act (농업기계화 촉진법), which dictates safety and inspection standards for all high-power machinery. Furthermore, soil management in the region is heavily influenced by the Farmland Act (농지법), ensuring that tilling and planting practices do not lead to excessive erosion or chemical runoff into water tables. Watanabe machines are designed to meet these stringent environmental requirements. Globally, for users seeking equipment in the EU or North America, our machines comply with ISO 4254 safety standards. Specifically, for those using rock rake implements for pre-planting soil preparation, international regulations in countries like Australia require that stone removal does not destabilize the topsoil slope—a principle that Watanabe engineers prioritize by maintaining the structural integrity of the soil bed during the planting pass.

7. Application Scenarios

1. South Korea – Precision Farming in Gangwon-do (Sloped Terrains)

Application: The PANTHER 2-row and 3-row models are ideal for sloped, rocky terrains, typical of regions like Gangwon-do. The high empty weight ensures consistent planting depth on steep hillsides, making it suitable for areas with irregular topography. The machinery’s ability to reduce labor costs and integrate fertilizer and insecticide application in a single pass is a key advantage in regions facing labor shortages.

Benefit: Enables efficient planting in challenging terrains while reducing the need for multiple machines and operators.

2. United States – Large-Scale Potato Farming in Idaho

Application: Idaho, one of the largest potato-producing regions in the U.S., requires high-capacity machinery for large-scale planting. The PANTHER 4-row model, with a 1200 kg seed capacity, fits the needs of commercial potato farms by maximizing operational efficiency. The machine’s sophisticated gearbox allows farmers to customize seed spacing, optimizing planting based on varying soil conditions.

Benefit: Increases the planting window efficiency, saving time and labor costs for large operations.

3. Australia – Commercial Potato Farming in the Murray-Darling Basin

Application: In Australia’s dry regions, like the Murray-Darling Basin, water conservation and efficient use of fertilizers are crucial. The Watanabe PANTHER series offers integrated fertilizer application, which reduces nutrient runoff, aligning with Australian soil and water management laws. The heavy-duty design ensures stability even on compacted or semi-rocky soils.

Benefit: Reduces water and chemical waste, aligning with Australia’s strict environmental regulations and sustainable farming practices.

4. India – Precision Agriculture in Punjab

Application: In India’s Punjab region, where farming is transitioning to more mechanized systems, the Watanabe potato planters can modernize operations. The PANTHER series’ ability to perform multiple tasks in one pass (seed planting, fertilization, and spraying) is particularly advantageous in areas where labor shortages are common, and efficiency is paramount.

Benefit: Increases labor efficiency, reduces manual intervention, and ensures uniform seed planting, crucial for large-scale crop production.

5. Russia – Industrial Potato Farming in Siberia

Application: In the vast and challenging terrains of Siberia, Russia, the PANTHER 3-row model’s ability to handle heavy loads with up to 1500 kg of seed capacity is critical. The machine’s compatibility with a range of tractor brands, including John Deere, ensures that even in remote regions, farmers can find compatible equipment for their existing machinery.

Benefit: Handles the harsh and cold Siberian conditions, providing reliable seed placement and fertilizer distribution to support the vast potato fields.

6. Brazil – Large-Scale Potato Farming in São Paulo

Application: In Brazil, where mechanized farming is growing rapidly, the PANTHER 4-row model can support large-scale operations in São Paulo’s fertile land. The advanced hydraulic system and high capacity fertilizer tank (600 kg) allow for consistent, high-quality potato production. Additionally, the high-speed functionality of 3-5 km/h speeds up planting, allowing farmers to cover large areas quickly.

Benefit: Increases productivity and reduces operational costs, helping to meet the growing demand for potatoes in Brazil’s expanding agricultural market.

7. United Kingdom – Commercial Farming in Scotland’s Highlands

Application: The rugged and often wet conditions of the Scottish Highlands present challenges for consistent planting. The PANTHER 2-row and 3-row models are well-suited to these conditions with their weight distribution and consistent depth control, ensuring that seeds are placed accurately even in damp, uneven terrain. The “One-Pass” operation allows for efficient use of labor, an essential factor in the UK where labor costs are high.

Benefit: Maximizes planting efficiency while minimizing soil disruption and ensuring environmental sustainability in the face of stricter agricultural regulations.

8. Market Trend Analysis:

The global agricultural sector is rapidly shifting toward “Smart Farming 4.0,” where data-driven precision is no longer optional. In South Korea, the rising cost of seasonal labor is driving a 15% annual increase in the demand for multifunctional planters. Farmers are moving away from potato planter diy kits toward integrated systems that can provide localized fertilization.

This “Point-of-Need” nutrient application reduces wasted chemicals by up to 20%, aligning with global ESG (Environmental, Social, and Governance) goals. Additionally, there is a clear trend toward higher seed bunker capacities (moving from 350 Kg to 1200 Kg) to optimize the efficiency of the planting window, which is increasingly shortened by unpredictable weather patterns in East Asia.

9. World Success Case:

Client 1 Profile: United States, Idaho Potato Farm Owner

Klantbeoardielingen:

“As a large-scale potato farmer in Idaho, efficiency is key, and the PANTHER 4-row model delivers just that. The high seed capacity means fewer refills, which is crucial when you’re planting hundreds of hectares. We also appreciate how customizable the seed spacing is, which allows us to adapt to different soil types and potato varieties. It’s a powerful machine that handles our demands, and the ROI has been incredible.”

Client 2 Profile: Australia, Murray-Darling Basin Farmer

Klantbeoardielingen:

“We’ve been using the Watanabe PANTHER series on our farm in the Murray-Darling Basin, and it has been fantastic for managing our water and fertilizer use. The precision planting and fertilizer distribution have helped us conserve water and minimize runoff, which is critical for us. The machine’s durability in tough conditions, like compacted soil, has been impressive, and it’s definitely a step up from the older models we used.”

Client 3 Profile: Russia, Siberian Potato Farmer

Klantbeoardielingen:

“Farming in Siberia is no easy task, but the PANTHER 3-row model handles the cold, rough conditions here with ease. The weight distribution helps the planter stay stable on our rocky soil, and it’s compatible with our existing tractors, so no need for additional equipment. The high seed capacity and fertilizer tank mean fewer stops during planting, which is crucial for our long planting seasons.”

Client 4 Profile: Brazil, São Paulo Potato Farm

Klantbeoardielingen:

“The PANTHER 4-row model has been perfect for our large-scale potato operation here in São Paulo. With the high seed and fertilizer capacity, we can cover large areas quickly without having to refill constantly. It’s great for meeting the growing demand for potatoes in Brazil, and we’ve noticed a huge increase in productivity since we started using it. It’s a reliable, efficient machine that really helps us manage our farm better.”

Client 5 Profile: United Kingdom, Scottish Highlands, Potato Farmer

Klantbeoardielingen:

“Farming in the Scottish Highlands is challenging, especially with the unpredictable weather and uneven terrain. But the PANTHER 2-row model has made planting potatoes so much easier. Its weight and depth control ensure that seeds are planted evenly, even in the wet, rocky soil here. The one-pass operation saves us a lot of time, and it’s helped reduce the amount of labor we need. It’s definitely made a big difference in how we operate during planting season.”

10. EVER-POWER Factory Capabilities & OEM Customization

We understand that soil conditions vary not only from country to country but also within different regions of the same country.

Our manufacturing facilities are equipped with advanced CNC machining equipment and robotic welding production lines, enabling us to provide exceptional customized services.

Unlike traditional fixed assembly lines, we can adjust the chassis reinforcement, tooth spacing, and hydraulic line layout of our rock rakes to suit specific regional needs, such as adapting to the heavy clay soils common in Southeast Asia or the dry, abrasive soils of the Middle East.

We offer OEM services to our distributors and can customize the connection system to suit specific tractors.

Whether you need a rock rake configuration for road construction or specialized equipment for agricultural production, our engineering team is ready to assist you.

11. About us

– Rock & Soil Equipment: Rock rakes, rock pickers, rotavators, rotary cultivators

– Potato-Specific Machinery: Potato planters, potato furrowers, potato diggers (2-row, trailed, 2-row trailed, 4-row trailed), potato harvesters (2-row, big-bag compatible), potato processing auxiliary equipment

– Livestock Machinery: Specialized equipment for livestock farming operations

– Agricultural Inputs: High-performance fertilizers

12. Replaceable parts

12.1. PTO Drive Shaft and PTO Gearbox

1. PTO Shaft

2. Agricultural Gearboxes / PTO Gearboxes

12.2. Agricultural Gearboxes (including various applications)

1. Rotary tiller gearboxes

2. Fertilizer spreader gearboxes

3. Rake & mower PTO gearboxes

12.3. Hydraulic Cylinders

1. Standard hydraulic cylinders

2. Custom hydraulic cylinders

12.4. Drive Chains / Sprockets / Couplings / Gear Components

1. Roller Chains

2. Chains & Sprockets

3. Couplings

13. Frequently Asked Questions (FAQ)

Q1. How much does a commercial potato planter cost for professional farming operations in South Korea?

A1. The price for a high-precision commercial potato planter varies depending on the row configuration and optional features like insecticide tanks. For the Watanabe PANTHER series, costs typically align with premium industrial machinery but offer a rapid ROI through labor savings. Please click our ‘Get a Quote’ button for current pricing and shipping estimates to your specific region.

Q2. Where can I find a reliable 3 point potato planter supplier near Gyeonggi-do for local maintenance?

A2. Watanabe equipment is distributed through a network of specialized agricultural hubs. We provide direct shipping and technical support to Gyeonggi-do and all other Korean provinces. Our factory engineers also provide 24/7 online diagnostic support to ensure your potato planter machine tractor stays operational throughout the critical planting window.

Q3. What is the recommended engine power for operating the heavy-duty PANTHER 4-row potato planter?

A3. To operate the Watanabe PANTHER 4-row model at its peak efficiency of $3-5~km/h$, we recommend a tractor with a minimum engine power of 125 cv. This ensures the hydraulic system has sufficient pressure to manage the high seed capacity of 1200 Kg and maintain consistent planting depth in varied soil conditions.

Q4. Which potato planter machine tractor is best suited for sloped hillsides common in Gangwon-do fields?

A4. For sloped or irregular terrains, the Watanabe PANTHER 2-row or 3-row models are ideal. Their high empty weight (1325 Kg – 1500 Kg) provides the necessary downward force to prevent “bouncing,” ensuring that your 3 point potato planter maintains a uniform furrow depth even on steep grades where lighter machines would fail.

Q5. When is the best time to replace the seed distribution gears in a used potato equipment for sale?

A5. We recommend inspecting the gearbox every 200 operational hours. If you notice uneven spacing or increased seed damage, it is time for a replacement. Because our machines use high-tensile components, they outlast most used potato equipment for sale, but genuine Watanabe parts are essential for maintaining the 16-combination precision.

Q6. How do I calibrate the fertilizer spreading rate on my new Watanabe PANTHER agricultural machinery?

A6. Calibration is managed through the mechanical linkages on the fertilizer bunker. By adjusting the gate opening and matching it to your tractor’s PTO speed, you can precisely meter out the 680 Kg of nutrients. This level of control is what separates a professional unit from a potato planter diy project or low-cost alternatives.

Q7. Why should I invest in a new Watanabe planter rather than a vintage potato planter for sale?

A7. While a vintage potato planter may have a lower initial cost, it lacks the integrated fertilizer and insecticide spraying systems of modern Watanabe machines. The PANTHER series allows for a “One-Pass” operation that saves massive amounts of fuel and time, making it a far more profitable investment for any serious commercial grower.

Q8. What is the best planter for potatoes?

A8. The best potato planter depends on your farm size and needs:

Three‑point PTO potato planters like the Watanabe PAI‑2100 or the PANTHER series are excellent. They combine seed, fertilizer, and insecticide application in a single pass, saving labor and time.

Best overall for commercial use: A multi‑row PTO planter with integrated fertilizer and precise spacing — e.g., a 3‑row or 4‑row PANTHER model.

Editor: PXY

*Disclaimer: The other brand names mentioned above are provided solely for illustrative purposes. We do not offer original products or equipment bearing these brand names.