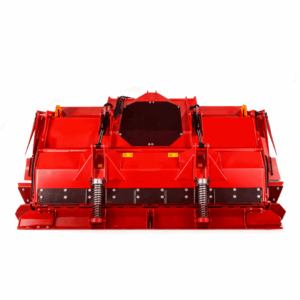

EP-Tractor-Mounted Rock Crusher

The Tractor-Mounted Rock Crusher provides a perfect solution for agricultural operations, solving the longstanding problem of obstructive stones that hamper crop growth and machinery efficiency. For land developers and agribusinesses, these stones are major barriers to higher yields and smoother workflows.

1. The Tractor-Mounted Rock Crusher provides a perfect solution for agricultural operations.

When hard rocks and thick stone slabs become obstacles in construction, the rock crusher provides the solution with 'Fixed Tooth Cutter, Hardcore Performance.' Compatible with 80-190hp tractors, it easily handles a maximum crushing diameter of 30cm and reaches a working depth of 28cm, meeting requirements directly. Whether for farmland preparation, road construction, or site clearing, it can precisely crush and level the base, making crushing operations not only about 'breaking' but also excelling in 'stability' and 'speed.'

2. Why Tractor-Mounted Rock Crusher Are Indispensable for Farmland Renovation & Pasture Clearing in Korea?

1. Tackling Korea’s Rocky Reality

Over 70% of South Korea’s landmass is mountainous, and many fields—especially in regions like Gangwon-do, Gyeongsangbuk-do, and Jeollanam-do—are littered with surface and subsurface stones. These rocks not only damage plows and tillers but also reduce soil fertility and water retention. Traditional manual removal is labor-intensive, costly, and often ineffective. Tractor-mounted rock crushers offer a mechanized solution that pulverizes fieldstone directly in situ, turning obstacles into beneficial soil aggregates.

2. Cost-Effective & Time-Saving Land Preparation

Unlike standalone rock removal machines or excavator-based systems, tractor-mounted rock crushers leverage existing farm tractors—maximizing ROI without requiring additional heavy machinery. Farmers can clear and condition land in a single pass, significantly cutting down renovation time from weeks to days. This efficiency is crucial during Korea’s short planting windows and aligns perfectly with the government’s push for smart, streamlined farming practices.

3. Aligns with Korea’s Agricultural Modernization Goals

3.Why Choose our Tractor-Mounted Rock Crusher?

In an era of increasing demand for agricultural mechanization and land restoration, our Tractor-Mounted Rock Crusher has become a preferred tool for farmland clearing and soil improvement with its innovative design and outstanding performance. Compared to traditional equipment, it redefines efficient operations through three core advantages: high-efficiency crushing, flexible adaptability, and durable construction. Specifically designed for rocky terrain, the machine effortlessly crushes rocks with diameters up to 30 cm while achieving strong power output through a gear-driven system, significantly shortening construction periods and improving land preparation efficiency. Its compact design ensures seamless operation in narrow spaces such as vineyards, orchards, and terraced fields, effectively overcoming spatial limitations faced by large-scale equipment in mountainous farms or fragmented pastures. Constructed with abrasion-resistant steel protection, a forged steel rotor shaft, and a sealed lubrication system, the machine significantly extends service life while reducing long-term maintenance costs. Meeting diverse needs from small farms to large ranches, it flexibly adapts to applications such as rock crushing, soil improvement, and turf laying. Choosing our Tractor-Mounted Rock Crusher means not only selecting a tool but investing in a future-oriented agricultural solution that prioritizes efficiency, durability, and adaptability.

4.Technical Specifications of Tractor-Mounted Rock Crusher

| Models | TMRC 100 | TMRC 125 | TMRC 150 | TMRC 175 | TMRC 200 | TMRC 225 |

|---|---|---|---|---|---|---|

| Trekker (pk) | 80-120 | 90-120 | 100-120 | 120-190 | 130-190 | 140-190 |

| PTO (rpm) | 540 | 540 | 540 | 1000 | 1000 | 1000 |

| Wurkbreedte (mm) | 1000 | 1240 | 1480 | 1720 | 1960 | 2200 |

| Totale breedte (mm) | 1410 | 1650 | 1890 | 2130 | 2370 | 2610 |

| Weight (Kg) | 1600 | 1800 | 1960 | 2350 | 2500 | 2650 |

| Maksimale fersnipperdiameter (mm) | 300 | 300 | 300 | 300 | 300 | 300 |

| Working depth (mm) | 150-280 | 150-280 | 150-280 | 150-280 | 150-280 | 150-280 |

| Rotor diameter (mm) | 595 | 595 | 595 | 595 | 595 | 595 |

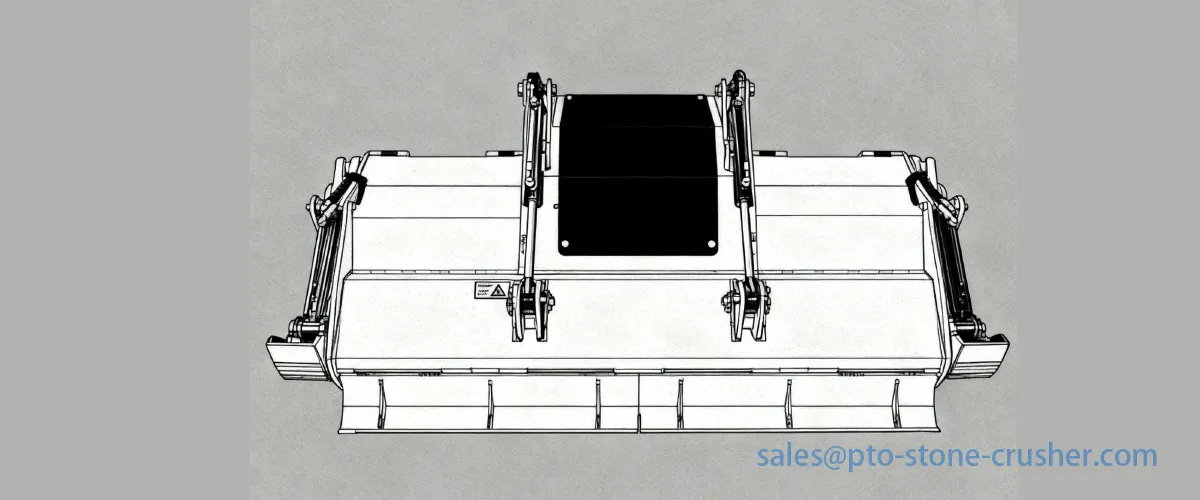

5.Analysis of our rock crusher advantages

In the competitive rock crushing equipment market, our Tractor-Mounted Rock Crusher stands out with the following core advantages, making it the preferred tool for efficient farmland renovation and pasture clearing:

- High-Efficiency Crushing, Breaking Limits

Compared to traditional equipment: Unlike common standalone crushers or excavator-mounted crushing heads, our machine achieves deeper rock fragmentation through a gear-driven system and a 30cm rock-processing capability. - Flexible Adaptability, Delivering Results in Compact Spaces

Compared to traditional equipment: Many crushers are restricted by bulky designs (e.g., tracked machines), making them unsuitable for narrow areas. Our machine features a minimum working width of 100cm and a lightweight build, perfectly adapting to complex terrains like vineyards, orchards, and terraced fields. - Durable Construction, Long-Term Investment Assurance

Compared to standard models: Ordinary crushers’ blades and chambers wear out easily, requiring frequent replacements. Our machine uses steel protection and a forged steel rotor shaft, combined with a sealed lubrication system, to significantly extend service life and reduce maintenance costs. - Smart Maintenance, Saving Time and Effort

Compared to traditional designs: Our hydraulic rear hood adjustment, quick-replace liners, and modular components make daily maintenance more efficient, minimizing downtime. - Customizable Solutions for Diverse Needs

Product options: Customizable colors, your brand logo, and pick type selection.

6.Customer Reviews and Case Studies of Tractor-Mounted Rock Crusher

Client1 Profile:

Kim Tae-woo, Apple Orchard Owner in Gangwon-do

Challenges

Rocky, sloped terrain limits mechanization and root development

Previous attempts with mini-excavators caused soil compaction and tree root damage

Klantbeoardielingen:

"My orchard is on a steep hillside full of stone—every time I tried to expand planting rows, the rocks would jam the tiller or damage irrigation lines. I tested two other mounted crushers last year; one overheated after 2 hours, and the other left sharp stone shards that cut through drip tapes. This rock crusher handled the slope smoothly, crushed everything down to gravel-sized particles, and didn’t tear up the existing soil structure. It fits between my apple rows without widening the tracks!!!"

Client2 Profile:

Choi Ji-young, Pasture Manager at a Cooperative in Chungcheongbuk-do

Klantbeoardielingen:

"We inherited 6 hectares of overgrown, stony pasture from a retiring farmer. We couldn’t afford a new high-horsepower machine, so we were skeptical when the dealer said this rock crusher works well even on a 95-hp tractor. But it did! Even better, the noise level is low enough that the nearby elementary school never complained during operation. For a cooperative like ours, reliability and cost-efficiency matter most."

7. Application Scenarios of the Tractor-Mounted Rock Crusher

- Farmland Renovation – Gangwon-do

Gangwon-do has many rice paddies and dry fields located in mountainous areas, often mixed with granite and basalt fragments. Farmers use tractor-mounted rock crushers before spring planting to remove stones from the soil, preventing damage to seeders and improving soil water retention. - Orchard Land Preparation – Gyeongsangbuk-do

Apple and pear orchards in areas like Yeongcheon and Andong are often on slopes containing large amounts of weathered rock. The rock crusher can clear new planting areas without damaging existing tree roots, providing a level and safe surface for orchard expansion. - Pasture Development – Chungcheongbuk-do and Jeollanam-do

Cooperatives convert abandoned hilly or idle land into pasture for dairy or beef cattle. The rock crusher efficiently processes surface and shallow stones, preventing hoof injuries to livestock and promoting even grass growth. - Organic Farm Soil Conditioning – Jeollabuk-do

Organic farmers must avoid damaging the soil ecosystem with chemicals or heavy machinery. The rock crusher precisely crushes hard stones without disturbing deeper soil layers, preserving microbial habitats and meeting organic certification requirements for land management. - Post-Disaster Land Rehabilitation – Southern Mountainous Regions of Korea

After typhoons or heavy rains cause landslides that cover farmland with debris, the rock crusher can quickly process leftover stones on-site, speeding up the return to cultivation.

Hawwe jo noch gjin brekker fûn dy't foldocht oan de easken fan jo projekt? Meitsje jo gjin soargen❗❗

As de stiennen op jo lân op in relatyf ûndjippe djipte begroeven lizze, hawwe wy ek oare searjes beskikber.

Bygelyks, de 150mm PTO Stienbrekker PSC Modellen, en de 200mm RockMaster Lânboustienbrekker.

As alternatyf binne der oare produkten foar in maksimale stienferpletteringsdiameter fan 500 mm, ûnder oaren.

8.Tractor-Mounted Rock Crusher After-Sales Guarantee and Support System

Us systeem foar tsjinst nei ferkeap is spesifyk boud foar Koreaanske lânbou- en lânbehearbehoeften.

Garânsjedekking:

Main structural components frame, rotor shaft, gearbox housing ,hydraulic systems and transmission parts,wear parts (e.g., picks, side liners) are covered for 6 months under normal use, in accordance with KS B 6301 agricultural machinery standards.

Tagong ta wrâldwide tsjinsten:

Wy leverje wrâldwide leveringstsjinsten.

Beskikberens fan reserveûnderdielen:

Standert ûnderdielen wurde lanlik binnen 1-2 wurkdagen levere fia CJ Logistics of Hanjin.

Bedriuwstraining en hantliedingen:

Elke oankeap omfettet in hantlieding foar operaasje en ûnderhâld yn it Koreaansk.

Klanttsjinst:

Korean-speaking technical team is available:

✉️ [email protected]

9. Oer ús

Wy binne in ynnovaasje-oandreaune profesjonele fabrikant fan pto-stienbrekkers. Mei mear as 50 jier ûnderfining yn 'e sektor en in djipgeand begryp fan klantbehoeften, leverje wy heechweardige brekoplossingen foar brûkers wrâldwiid.

- CE-sertifikaasje foar masinefeiligens (foar EU-merk)

- Grade A-sertifikaasje foar de yntegraasje fan ynformatisaasje en yndustrialisaasje

- SGS-ferifiearre fabrikant

- En oare troch de yndustry erkende kwalifikaasjes

- CNC-ferwurkingssintra

- Laser- en plasmasnijsystemen

- Robotyske laszellen

- Automatisearre gearstallingslinen

- Waarmtebehanneling en oerflakteôfwerkingssystemen

- Koördinaatmjitmasines (CMM) en ynline-ynspeksje-ark

- Digitale fabryk- en yndustriële softwareoplossingen

- Dynamometer teststasjons

- Smart Warehousing & Logistike Systemen

10. Us Tsjinsten

Wy leverje folsleine one-stop-tsjinsten fan oerlis en oankeap oant stipe nei ferkeap: ús profesjonele team helpt jo modellen sekuer te selektearjen, en it team nei ferkeap leveret ynstallaasjebegelieding, technyske stipe op lange termyn en levering fan orizjinele reserveûnderdielen om in stabile wurking fan 'e apparatuer te garandearjen.

Ynteressearre yn ús produkten en tsjinsten? KONTAKT MEI ÚS OPNIMME

11.FAQ:

F1. Foar hokker soarten terrein is dizze rotsbrekker geskikt?

A1. It is ûntworpen foar rotsich, ûneven terrein lykas berchpleatsen, boomgaarden, wyngerds en terrasfjilden. Mei in minimale wurkbreedte fan 100 sm wurket it effektyf yn smelle romten en kin it rotsen oant 30 sm yn diameter ferpletterje.

Q2. Is de masine maklik te ûnderhâlden?

A2. Ja. It hat in modulêr ûntwerp mei hydraulyske ferstelling fan 'e efterste motorkap en fluch te ferfangen liners, wêrtroch routineûnderhâld ienfâldich en rap is. Slijtvaste materialen ferminderje ek de frekwinsje fan ûnderdielferfanging.

Q3.How do I choose the right model for my tractor?

A3. Wy biede wurkbreedtes fan 1000 mm oant 2200 mm, kompatibel mei trekkers fan 80 oant 190 pk. Selektearje in model op basis fan it pk-fermogen en de fjildomstannichheden fan jo trekker, en ferwize nei ús technyske spesifikaasjes foar de juste ôfstimming.

F4. Wat moat ik dwaan as ik in technysk probleem tsjinkom?

A4. Nim kontakt op mei ús stipeteam fia e-post op [email protected].

F5. Is de masine miljeufreonlik?

A5. Ja. It wurket mei leech lûd en lege útstjit, wêrtroch it geskikt is foar biologyske pleatsen en gebieten tichtby wenwiken.

F6. Biede jo training foar operators?

A6. Ja. Wy leverje in hantlieding foar operaasje en ûnderhâld yn it Koreaansk mei fideotutorials mei QR-keppelings.

F7. Kin it brûkt wurde foar lânrehabilitaasje nei in ramp?

A7. Ja. It ferwurket effisjint pún en stiennen dy't oerbliuwe nei tyfoanen of lânferskowings, wêrtroch't lânbou fluch wer mooglik is foar kultivaasje.

Q8. Kin de masine oanpast wurde?

A8. Ja. Oanpassingsopsjes omfetsje kleur, jo bedriuwslogo en ferskate kartypen om te foldwaan oan spesifike operasjonele behoeften.